Study of Respiratory System Illness in Process Industries

Volume 3, Issue 3, July – September 20

Study of Respiratory System Illness in Process Industries

Rozi Firdos

BHMS (Scholar) from MHMCH, Muzaffarpur

Email id: firdosrozi@gmail.com

Abstract

In Process industries, every year several peoples suffer with respiratory system illness and such respiratory illness also results death of people in severe cases. Human body is made of different organ system in which one major organ system is respiratory system. Respiratory system work of breathing and it is known as inhalation and exhalation. Respiratory system can be effected due to exposure of poor air quality or generated hazardous agents of workplace. In industries, several type of occupational health diseases occur in which one major types of diseases is respiratory illness. In this study, function of respiratory system covered, potential sources of harm to respiratory system is also identified and how such illness occurs due to exposure is described. In this study, effective control measure including health study of employees also included to prevent disease related to respiratory system or minimize respiratory illness related risk. Therefore, this paper is very helpful to control respiratory illness that occur due to exposure of hazardous agent or poor quality of air that generates during process facility or operation in process industries.

Keyword: Occupational health, Hazardous agent, workplace poor air quality, Respiratory system illness or disease, Respiratory system illness prevention, Risk control

Objective

Objective to conduct this study and publish paper is to identify potential sources of respiratory system illness of workplace and ensure their effective control measure to eliminate or minimize such risk and to prevent occupational respiratory disease or death. To prevent such respiratory illness or diseases, increase organization reputation and improve occupational health safety performance in process industries.

1. Introduction

Occupational health safety is major parameter to grow business of any process industries. In process or chemical industries, availability of different sources or situation or release/emit fumes or gases or dusts during material storage and process facility, results health disease due to their hazardous nature and these sources has also potential to cause harm to environment. Few sources have potential to cause harm to human respiratory systems due to exposure of such gases or vapors or dust that are present at workplace in industries. Exposure to employees may be several ways/routes such as inhalation, skin contact, ingestion or injection but majority of respiratory illness occurs due inhalation of poor air quality or hazardous agent.

Human body structure is same as machine. Human body are made up of different components such as cells, Tissues, organs, Systems. A organ system is major components units of human body. Human organ system work with different component of body together to alive. Integumentary, skeletal, muscular, cardiovascular, endocrine, nervous, respiratory, lymphatic, digestive, urinary, and reproductive systems are major organ system of human body. Organ systems are the most complex component units and perform complex functions for the human body.

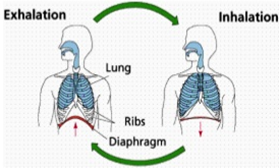

Fig. 1, Inhalation & Exhalation

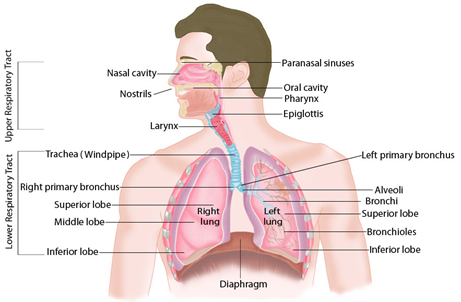

Respiratory system is a group of organs and it is responsible for breathing. Lungs is primary organ of respiratory system and it includes nasal passage, pharynx, oral cavity, larynx, trachea, bronchi and bronchioles. Respiratory system exchange to oxygen and carbon dioxide between the human body and air, acid-base balance regulation, phonation. Respiratory system work with different human body components to fulfill human need to alive.

There may be several causes of person death in industries in which one causes are respiratory disease. Respiratory system disease may be allergy, asthma, bronchitis, lungs cancer or other and such disease are notified in respective state or country legislation. In India, few respiratory diseases that concerned with factories are notified in schedule of III of The factories Act 1948. Respiratory illness may be results breathing problem, allergies, bronchitis, asthma, Pneumonia, lungs cancer and damage to any components of respiratory system due to inhalation of Poor quality air or mixed hazardous agent with air. Respiratory system can be subdivided into upper respiratory track & lower respiratory track (Fig. 2).

Fig. 2, respiratory System

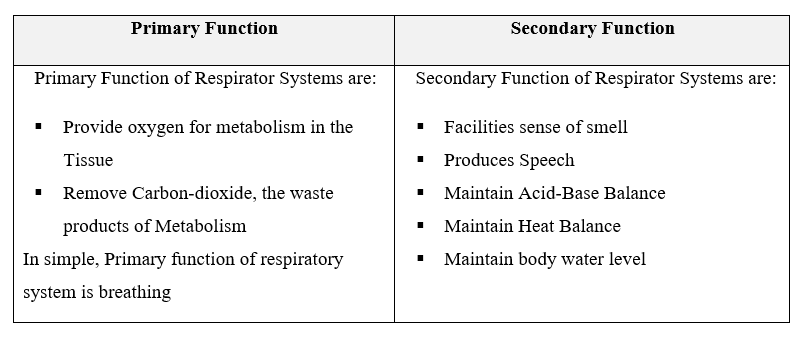

2. Function of Respirator System

Respiratory system is group of organ and tissue that help us to breathe. Respiratory system helps to absorb oxygen from air and transmit to lungs, organs, bloods, and remove to waste gases such as carbon mono-oxide (CO) from blood and organ through exhalation. Respiratory system work for respiration (breathing). This is major components of human body. Respiration process divided in two parts

- Inhalation (Inspiration)

- Exhalation (Expiration)

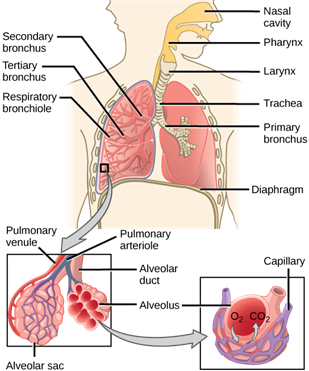

External respiration is also known as breathing and it involve bringing air into lungs (inhalation) and release air to the atmosphere (Exhalation) from body. In Internal Respiration, Oxygen and Carbon Dioxide (CO2) are exchanged between the cells and blood vessels of body. Major function of Respiratory System is gas exchange, Acid base balance, Phonation, Pulmonary defense and the handling of bioactive materials. Respiration start from nose or mouth.

Fig. 3, Respiratory system

Table 1, Functions of Respiratory System

3. Potential sources or agents that create respiratory illness

Many substances or agents found at workplace in process industries that can harm to respiratory system and it results respiratory illness or disease. Such diseases occur due to exposure of hazardous gases (toxins) or dusts or fumes and it irritate to the lining in human lungs. Few major potential sources that results respiratory system illness or diseases include:

- Fumes, Fine particles and similar hazardous sources that emits during welding, gas cutting, brazing, furnace work, manufacturing of plastic and rubber operation, pottery making and others work can result respiratory illness.

- Coal dust, cotton dust, wood dust, silica and asbestos particles harmful for lungs. Pesticides, enzyme or drug powders and fiberglass can also harm to lungs.

- Inhalation of smoke that generates from burning materials harm to lungs. Smoke contains a variety of particles, vapors and gases and it increase the risk of respiratory illness.

- Mists or sprays from paints, varnish, hair spray, pesticides, cleaning products, acids, oils, and solvents create respiratory illness.

- Gases such as formaldehyde, ammonia, chlorine, sulfur dioxide, and nitrogen oxides emits/release during chemical operation may results respiratory illness. Several chemicals use in lab can also harm to lungs.

Several liquids form vapors and such vapors have potential to cause harm to lungs. In cement or metal industries there may be several sources lead to cause of respiratory illness due to inhalation of lime stone dust or coal dust or cement dust or other similar hazardous dust or fumes or vapours.

4. Factor that Effect to respiratory system

Respiratory illness in industries depends upon several factors. Few factors that contribute to increase or reduce risk to respiratory illness are:

- Availability of Hazardous agent/ poor Air quality at workplace

- Route of exposure

- Human body susceptibility

- Health Surveillance

- Use of Personnel Protective equipments (PPE’s)

- Work rotation and duration of work/ limit of exposure

5. Type of effect & Symptoms of un-healthy respiratory System

Exposure of hazardous agent may be acute or chronic effect. Acute effect means short-term exposure of hazardous agents. Such effect occur due to inhalation of hazardous gases/dust/fumes or poor quality air and it immediate effects to organ and tissue of respiratory system. Chronic effect means long-term exposure of hazardous agents and harm or effect to organ and tissue of respiratory system. In case of infection or un-healthy respiratory systems below symptoms can be seen

- Shortness of breath/ difficulties in breathing

- Wheezing or Cough

- Chest tightness

- Sensation or minor pain in chest

- Weakness/ Lack of energy

- Frequent respiratory infections

- Unintended weight loss (in later stages)

In Few case, un-healthy respiratory system symptoms shows fever, minor pain in head, running nose or vomiting. A chronic cough that may produce mucus (sputum) and it may be clear, white, yellow or greenish. In Severe stage of respiratory illness, it may results lungs cancer or failure of respiratory organs and person can die. Lungs manage required oxygen level to body organ and If person unable to receive adequate Oxygen/air then he feel shortness of breath or cough or wheeze and such symptoms showing stage of respiratory illness.

Fig. 4, distinguish between healthy lungs & un-healthy lungs

6. Major respiratory illness or disease occur in industries are

Major Respiratory Illnesses and diseases in industries may be:

- Occupational/work related asthma.

- Chronic Bronchitis.

- Cystic Fibrosis/Bronchiectasis

- Chronic Obstructive Pulmonary Disease (COPD)

- Emphysema.

- Pleural Effusion.

- Pneumonia.

- Lung Cancer.

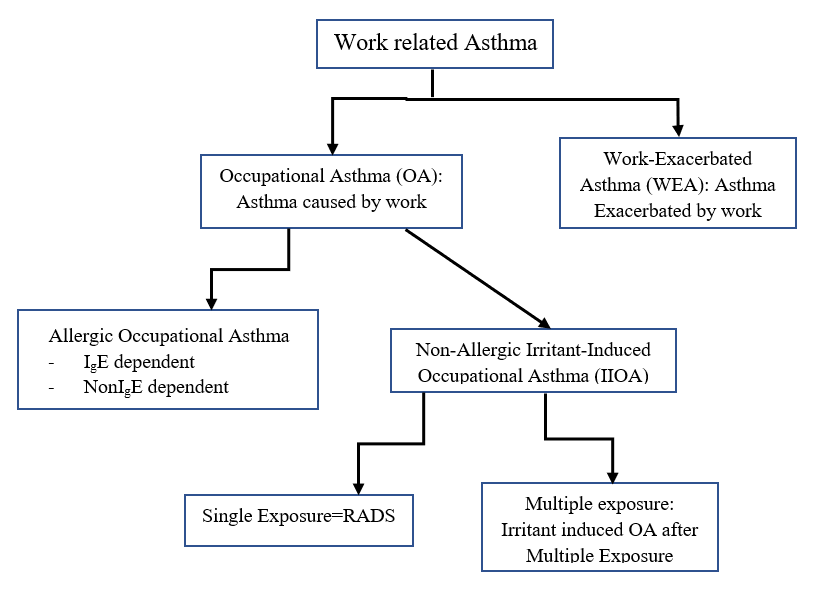

6.1 Occupational Asthma: Occupational asthma is respiratory system disorder, caused by breathing in hazardous fumes, gases, dust or other substances at workplace. Asthma can be develops in person due to single exposure (Acute effect) or multi exposure (chronic effect). Reactive airways dysfunction syndrome (RADS) and it is also known as acute irritant-induced asthma. Work related asthma can be categorized in below way:

Fig. 5, work related Asthma

6.2 Chronic (Industrial) Bronchitis: Bronchitis is inflammation of the large airways of the lungs that occurs in employees who work in poor quality area of process industries. Inflammation is also known as swelling. Similar above illness disorder to respiratory system and symptoms may be varies as per nature of diseases. Presence of asbestos particles at workplace may lead to cause of asbestosis, silica particles can result silicosis and other several particles found at workplace of process industries that may results respiratory illness due to personnel exposure.

Apart from this cough, shortness of breath, minor fever like symptom also seen in case of respiratory illness. In Severe stage, it may cause of lungs cancer, failure of respiratory system and its results death.

7. Study Results

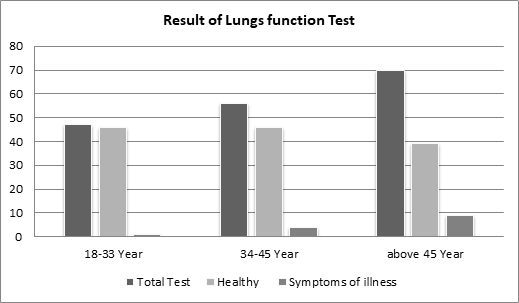

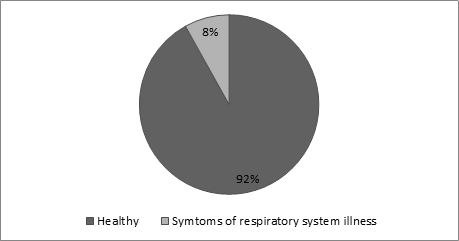

To know and identify respiratory system illness symptoms among working personnel of process industries, lungs function test conducted on 173 employees including workers of different age group and found symptoms of illness, age above 45 is more respect to age below 45 year of employees. Lungs function test conducted through spirometer and this is known as pulmonary (lungs) function test. In total 173 employees, 14 employees found symptom of respiratory illness in which 11 were very mild symptom. On based on symptoms, we can’t confirm that person is sustaining from respiratory system illness/disease till deep examination/investigation not conducted by specialist doctor. Counseling also conducted of employees to know their breathing condition and based on this analysis, chart drawn (Fig. 6 & Fig. 7).

Fig. 6, Healthy and unhealthy lungs (on based on symptoms of illness) age wise

Fig. 7, Percentage of healthy and unhealthy lungs (on based on symptoms of illness)

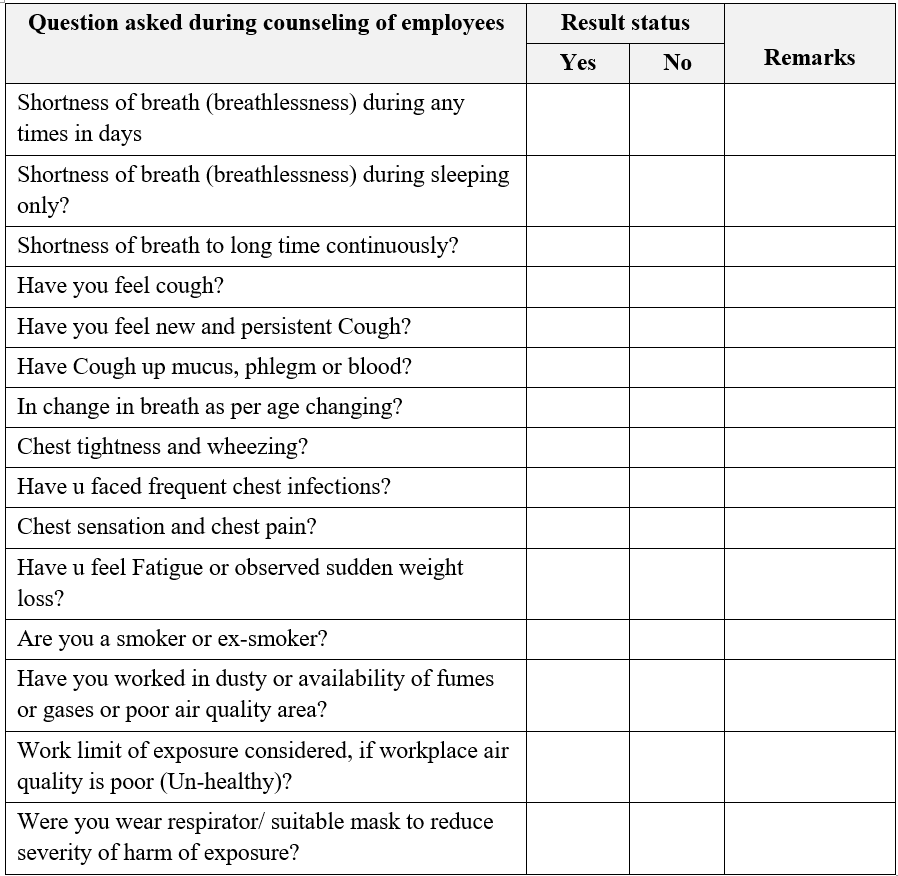

Table 2, Question asked during counseling of employees

Spirometer device is used to check the performance of human lungs (fig. 7).

Fig. 7, Pulmonary (lungs) function Test

8. How can occupational respiratory illness/ disease diagnosed?

Any person feeling symptoms of breathing difficulty or suspecting respiratory illness, Need to consult with company doctor. Doctor will review symptoms and conduct counseling to ask such question:

- When you feel/appear first Symptoms?

- How often do you symptoms?

- Your nature of work, working time, duration of work on daily basis and have you contacted with any chemical or Hazardous agent?

- Have you face any breathing problem during work?

- Earlier any of your team member that are working with you, infected or sustained any respiratory illness?

- Are you smoker?

Doctor will also ask question about previous job history including respiratory illness, existing Safety control measure at work place, were you wearing safety mask etc.

For this, company doctor should deep knowledge about work environment, presence of hazardous agent in work environment and knowledge about Material safety Data sheet (MSDS). Record to symptoms and completed in Occupational Health history form. On based on this, doctor will study patient history as per presence of hazardous agent in work environment and potential risk of exposure to health and recommend for test. Doctor may order a breathing test can listen to your lungs and see how they are performing. Doctor can recommend for pulmonary function tests, chest X-ray or CT scan (Thorax), bronchoscopy to detect actual cause of respiratory illness/ Disease. CT scan will help to detect masses, fluid, or inflammation of lungs. Bronchoscopy helps to diagnose lung problems, look for blockages, take out tissue or fluid samples for further test or remove a foreign body.

Doctor will carried out depth study and conduct testing to determine types of respiratory disease and severity. On based on this, doctor will start to give treatment or recommend to patients for consultation with specialist for better diagnosed. Other test such as blood gas can also conduct to measure amount of carbon dioxide and oxygen in the blood. Doctor can recommend or conduct test as required to look possible infections and other problems.

9. How can prevent to respiratory disease in Process industries

Respiratory disease can be prevented through effective safety control measure including reduce exposure limit to minimize risk related to respiratory illness up to tolerable level. Carry out workplace air quality Assessment of storage and process facility area, evaluate to associate risk and if risk is not tolerable then need to take adequate control measure. Following are few methods to control respiratory illness/ disease

- Identify Potential source of harm to respiratory system illness and assess the risk.

- Ensure Effective Engineering control measure.

- Workplaces should have respiratory illness prevention plan/ programs to monitor and limit exposure.

- Health monitoring must be conducted on regular interval.

- Wear suitable and standard respirator to avoid severity of harm of exposure.

- Increase ventilation in work area, whenever require.

- Avoid eating or taking rest at workplace area.

- Take healthy diet.

- Need to plantation at workplace area, whenever required

- Know about job, workplace hazard and take adequate safety measure accordingly

- Time to time conduct workplace air quality test.

10. Occupational respiratory disease treatment

There is no effective cure for occupational respiratory disease. Treatment can only help reduce symptoms and prevent further damage. It can also help to improve health condition. Treatment types include use of medicines, inhalers, and/or oxygen, avoid or limit exposure and take dietary food. Severe conditions may require a lung transplant. In case of any difficulties in breathing, contact with company doctor, doctor will examine and give treatment as per based on symptoms and illness.

11. Conclusion

Respirator system is major organ of human body that work as inhalation and exhalation. It brings oxygen from air and transport to lungs. In process industries several sources presence and effect to respiratory system due exposure. Respirator system can be effected due short term effect or long term effect. Respirator system can be prevented to ensure effective engineering control measure and respiratory illness program and reduce limit of exposure. Identify Potential risk and effective control measure to minimise risk upto tolerable level.

Organic dust found in the agriculture, food packaging, and weaving industries can create respiratory diseases such as farmer’s lung, allergic alveolitis, occupational asthma, byssinosis, chronic bronchitis, chronic airflow limitation, and organic dust toxic. Dust, fumes or vapours emits from cement industries, metal industries or chemical industries may lead to cause of respiratory illness risk due to exposure and such risk can be control through adequate safety measure.

References

- E. E. Koehn and N. K. Datta, “Quality, environmental, and health and safety management systems for construction engineering,”Journal of Construction Engineering and Management, vol.129, no.5,pp.562–569,2003.

- Topuz, E., Talinli, I., & Aydin, E. (2011). Integration of environmental and human health risk assessment for industries using hazardous materials: A quantitative multi criteria approach for environmental decision makers. Environment International, 37, 393–403.

- Sese´, A., Palmer, A.L., Cajal, B., Montano, J.J., Jime´nez, R., & Llorens, N. (2002). Occupational safety and health in Spain. Journal of Safety Research, 33, 511– 525.

- DOSH. (2014). Gas Contractor (Petroleum pipeline) Company. Retrieved from Department of Occupational Safety and Health: 18 Aril 2014 http:// www.dosh.gov.my/index.php?option=com

- Mishra, G. P. 1991. “Impact of industrial pollution from a cement factory on water quality parameters at Kymore.”Environment & Ecology 9(4): 876-880

- World Health Organization. Hazard prevention and control in the work environment: Airborne dust. 1999. Available from: http://www.who.int/occupational_health/publications/airdust/en/. Accessed on: [June 12, 2017].

- Alemu K, Kumie A, Davey G. Byssinosis and other respiratory symptoms among factory workers in Akaki Textile Factory, Ethiopia. Ethiopian Journal of Health Development. Issue. 2010;24(2):133-140.

- O’donnell DE, Hernandez P, Kaplan A, Aaron S, Bourbeau J, Marciniuk D, et al. Canadian Thoracic Society recommendations for management of chronic obstructive pulmonary disease–2008 update–highlights for primary care. Canadia

- Yang CY, Huang CC, Chiu HF, et al., Effects of Occupational dust exposure on the respiratory health of Portland cement workers. J. Taxicol. Environ. Health. 1996; 49: 581-588.

- ISEI Manuals