An Adequacy Approach Study For Calculating The Amount Of Water To Be Stored In The Pharmaceutical Industry For Tackling The Emergency Situation Like Fire

Volume 4, Issue 3, July – September 21

Study For Calculating The Amount Of Water To Be Stored In The Pharmaceutical Industry For Tackling The Emergency Situation Like Fire

Dr. A. Yudhistra Kumar

Student Member –IEEE, Research Scholar VISTAS Chennai

Email id: yudhistrakumar@gmail.com

Abstract

Considering the hazardous nature in the pharmaceutical industry (API), a study has been conducted to calculate the amount of water to be stored in the industry to tackle the emergency situation like fire, where highly toxic, hazardous and flammable materials are stored and used in the manufacturing process as per the instructions given in the Batch Management Record (BMR). Based on the water load calculated, we have ascertained scientific approach to know the quantity of the water required in case of the fire emergency, which has resulted in an adequacy approach.

Key words: Chemical industry, API, BMR, Hazardous and flammable materials and Fire Emergency

1. Introduction

Fire is the combustion process of burning, its components are oxygen, fuel and heat (Robertson (1984)). It is a chemical reaction, initiated by the sources of heat energy with the flammable chemical substance at a particular temperature in presence of sufficient oxygen. The vapours present in the working environment in the API industry, which are flammable and hazardous in nature. The heat source and the sufficient fuel, in the form of chemicals in presence of sufficient oxygen, which initiates the chain reaction process, which is known as fire ((David M Wharry & Ronald Hist (1992), Jain (2010), Sesha Prakash (2013) and Gupta. (2009)). The fire chain reaction happens due to the chemicals used or the combustible dust or the combustible substances or the different vapour mixtures, which will lead to the fire accident when all the three components of fire are present in the equal proposition. This continuous stage of fire, where the chain reaction is continued is called burning. During this burning stage, the process will emit energies. The energies will be in the form of heat, light and sound. The burning extinguishment will happen when the sources of heat energy is absent or if the heat energy is not having required level of heat capability to continue the reaction in the form of fire, where the combustible chemical substances is absent or the oxygen supply is less to support the reaction of the fire to continue. The heat sources are available in the buildings comes from the electrical appliances, gas appliances, chemical substances both in the form of the liquid and solid, which are used in the process to achieve the desire reaction. The mechanical equipment’s, which are used in the API industry during the various processes in order to make the finished goods, i.e., reactors, centrifuges, driers, multi mill, jet mill and shifters also generate heat during the running operation. The combustible fuel substance is available in the buildings are in the form of combustible materials (every day activities required chemical materials which are used in the process to enhance the reaction and achieve the desired results, which is in the form of a finished goods). These combustible materials of various types with different quantity will be kept in different location based on the requirement of the process, although major chemical substances are stored in the raw material and procurement materials storage area, these materials are used in the intermediate blocks, dryer blocks and finished goods, where different activity is carried out in the API industry by using various chemicals and solvents, where there are higher chances that the chemical substance can catch fire in case of sufficient safety measures are not followed during the storage, handling of the chemicals in the process.

In an increasing demand over the use of chemicals in the manufacturing process, which are used by the human beings have been resulted in handling the risky situation and tackling the emergency situation like fire. The water supply needed to tackle the emergency is based on the economic supply of water (Aashish Yadav and Prof. Praveen patel (2014)). In the past times the water supply is required for the development of the cities, towns and villages across the world but considering the emerging modern API chemical industries across the globe, the fire protection of their resources in the factory has to play a vital role in tackling the emergency situation. However, considering the present situation it was found that there is large quantity of water existed in the globe in the form of perennial and non-perennial rivers, ponds, lentic and lotic systems, which paves a way of suppling the water to tackle the fire in the industry. By giving the importance to fire tackling situation from the late nineteenth century, this has resulted in additional cost of water works to be provided for firefighting, which has resulted in the inequalities among the industries for the additional cost to be laid for providing the water for tackling the emergency situation like fire. (Comeau and Duval (1998), Covey (1999) and Damon (1993)) demonstrated the individual waterworks disparities and their problem and presented their findings in the various technical papers, conferences, journals and the engineering society meetings. It has been initiated and recommended to have an environment sustainability approach for tackling the fire by saving the rain water in the factory premises, by Channeling and collecting the water in a manmade pond, which a novel divine approach. It is always necessary that an organization should know the adequacy water to be stored in the industry to tackle the emergency situation like fire.

2. Methodology used for Fire Load Calculations

As per the Rajasthan Factories Rules (GFR) 1963, Rule 63 (12) states that the every factory adequate provision of water-supply for firefighting shall be made and where the amount of adequacy of water, which is recommended is 550 liters/minute or which is obtained by calculating from the below formula. Power driven transfer pump with the sufficient capacity has to be installed.

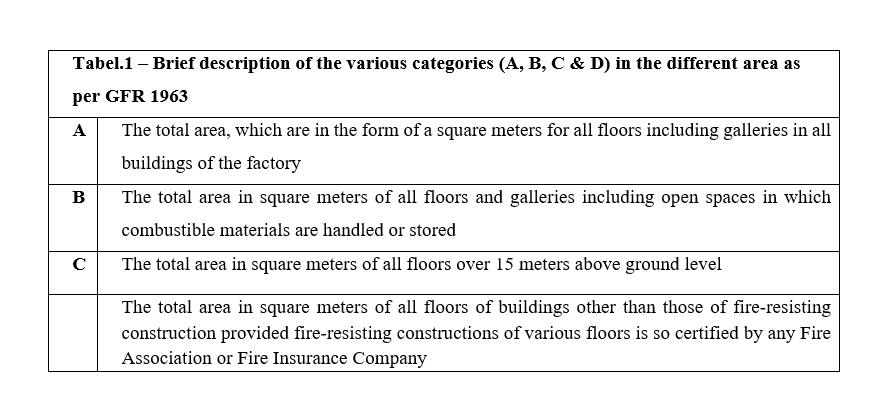

Water required in liters per minute can be calculated by using the formula (A + B + C + D )/ 20, the below table gives a brief description of the four categories.

In the above formula –

Provided that, in areas where the fire risk involved does not require use of water such areas under A, B, C or D may, for the purpose of calculation, be halved: Provided further that, where the areas under A, B, C or D are protected by permanent automatic fire fighting installations approved by any Fire Association or Fire Insurance Company.

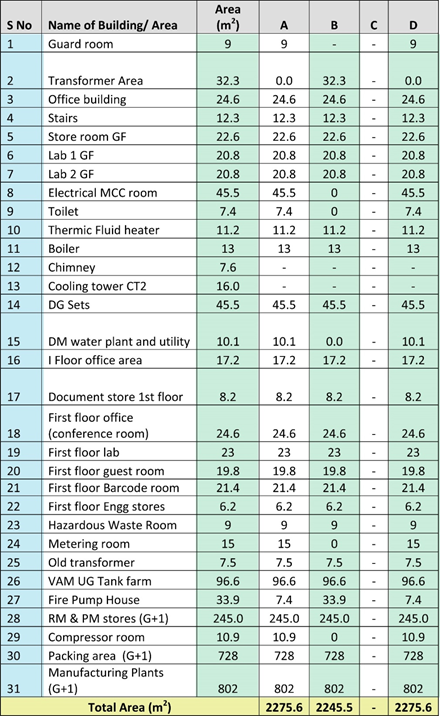

Results and discussion – During the study, each area has been measured in the factoryas per the methodology recommended by the GFR 1963

Table 2. Fire Load Calculations

Tabel – 2 (a) Fire Load Calculations – area (m2) with their different categories as per GFR 1963 rules

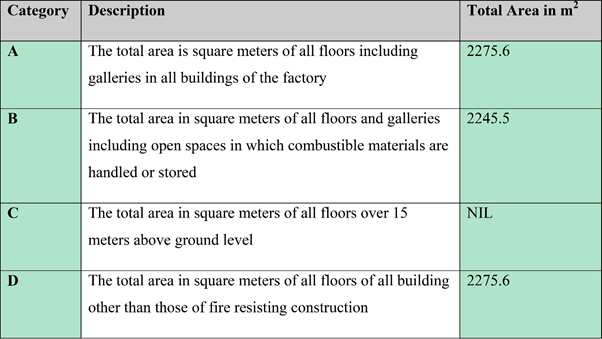

Water required for firefighting in Lit/min can be calculated (A+B+C+D)/20 (Table. 2(a), which is equal to 339.8 Lit /minute ((0.33 m3 /minute), (20.39 m3/hr)). Water requirement is less than 550 Lit/ minute therefore power-driven trailer pump is not required.

From the above Tabel. 2, it has been observed that the highest area is the manufacturing area (802 m2), followed by RM and PM stores (245 m2) and lowest area being engineering stores (6.2 m2), which is located at the first floor. The manufacturing is the area, where the highest hazardous materials are used in the process for manufacturing of the Intermediates and finished goods, while raw materials stores where the highest toxic and fire hazard materials are stored in the respective allocated places. The engineering stores, where least hazardous materials are stored. Considering the above Tabel.2, the total area of various categories of A (2275.6 m2), B (2245.5 m2) and D (2275.6 m2), the category C, where total area in square meters of all floors over 15 meters above ground level was nil.

By considering the total water required for firefighting in Lit/min = (A+B+C+D)/20, which is339.8 Lit /minute (20.39 m3/hr) (Tabel.2(a)). As per GFR 1963 Rule 66A, the water required for fighting the fire to be stored for 100 minutes for fighting the fire to be calculated, so we can calculate the fire water required by using the formula ((A+B+C+D)/20) x 100 minutes, so water required to be stored for fighting the fire is 33980 Lit (33.9 m3). We do have 40 m3 of fire water stored in the storage pond, which is sufficient to fight the fire for 100 minutes.

3. Discussion

Many of the studies and approaches for the adequacy for the storage of the water in the pond has been published in the international journals although there is very less information, which is published in the national level for knowing the water load to tackle the fire emergency, especially with respect to the chemical industry such as API, where more hazardous substances like chemicals and solvents are stored and used in the working environment, taking the above scenario, in case of any eventuality in the API industry (like fire accident, which are caused due to various sources such as static electricity, exothermic reaction, accumulation of dust particle, solvent vapours and electrical short circuit) we do require sufficient water to be stored in the water storage pond in order to fight the emergency situation like fire for which water load calculation playing a vital role in the API industry, where hazardous substances are stored, which may cause fire due to the unsafe conditions and acts. Many of the international authors have published their work with respect to the fire load and they have used different type of approaches for calculating the fire load, which are used globally. Hadjisophocleous & Fu (2004) has reported that many of the international universities such as Lund University has developed two fire risk assessment approaches, standard Lund QRA (Quantitative Risk Assessment), and extended QRA. The standard QRA is most frequently used in describing risk in the chemical process industries. The quantitative fire risk assessment method, safety or risk can be evaluated either by comparing the existing design area with accepted solutions or with specified tolerable levels of risk. The former is a relative risk assessment method (QRA), is assessed in this paper. Considering the present study, which has been resulted in an adequacy quantity of water, which has been found in the fire water storage pound. It is often argued and said the solutions of the respective design, which are to be in the acceptable level, when we compared with the incorporated safety level (Fischer (2014) and Lundin (2005), It is often known as a benchmark for ‘adequate safety’. Then, the adequacy is an ‘innovative’ or ‘traditional’ approach has been demonstrated by comparing its safety level associated with the various categories as per the guide lines given in the GFR rules 1963, which is recommended by the inspector of factories, this is a common procedure to justify deviations from prescriptive methodology, although it will be varied globally (Grubits (2010), Fischer(2014) and Wu et al., (2014)), which are significant in obtaining the safety levels, allowing for an easier acceptance by the authorities and reducing the required complexity in the input data for calculating the water load (BSI (2003)). The adequacy approach, which helps the Environment, health and safety professionals to tackle the emergency situation like fire by storing the sufficient water in the water storage pond.

4. Conclusion

During the study it was observed that we do have adequate water stored in the water pond to tackle the emergency situation arises in the API industry. It is concluded that the adequacy can be considered to give a robust indication of the acceptability of a design, The GFR 1963, Rule 63 (12) recommended guidelines has helped us do an adequacy study for knowing the water load required to tackle the emergency situation. Although we expect all the safety precautions will be taken by the factory people to avert fire accident during the storing, movement of chemicals and its usage during the different kind of operations, let us finally say “Let us be safe, obey the safety guide lines. All the employees and contractors has been trained to tackle the emergency situation like fire in an industry”.

References

- Aashish Yadav and Prof. Praveen patel (2014).Assessment for water requirement and calculation for fire flow rates in water based firefighting installations. International Journal of innovation in engineering and technology, Vol.4, issue.1, pp. 5

- BSI. (2003). PD 7974-7:2003 – Application of fire safety engineering principles in the design of buildings – Probabilistic risk assessment. British Standard.

- Comeau and Duval (1998). School Fire pangnirtung, Northwest Territories, Canada, March 9, 1997. National Fire Protection Association. Quality, NA, NFPA Fire Investigation Report.

- Covey, B (1999). Static Water Supply Challenges, Australia’s solution, Fire Engineering, Vol. 152, No.8, 1999, pp.143-144

- Damon. W.A (1993). Testing Pressure Regarding Devices in water Based Fire protection system. Fire Engineering, Vol.146, no.11, pp.51, 55-57.

- David M Wharry& Ronald Hist (1992). Fire Technology Chemistry & Combustion, Institution of Fire Engineers, Belvoir offset limited Publication, England

- Fischer, K. (2014). Societal decision-making for optimal fire safety. Doctoral thesis, ETH-Zurich.

- Gupta. R. S (2009). A hand book of Fire Technology, University Press, Hyderabad. India.

- Grubits, S.(2010). A Risk-based Equivalence Approach to Fire Resistance Design for Buildings. Journal of Fire Protection Engineering, 20, 5-26

- Hadjisophocleous, G.V and Fu, Z (2004). International journal on Engineering Performance-Based Fire codes, Vol. 6, no.1, pg. 28-45

- Jain V. K (2010).Fire Safety in Buildings, New Age International Publication, New Delhi, India.

- Lundin, J. (2005). Safety in case of fire – The effect of changing regulations. Doctoral thesis, Lund University

- Robertson J.C (1984).Introduction to Fire Prevention, Mac Mill on Publication, New York.

- SeshaPrakashN (2013). Manual of Fire Safety, CBS Publication, New Delhi.

- Wu, Z., Li, H., He, Y., Zhou, D. and Wang, J., (2014). Comparative Evaluation Method for Fire Safety Design of Large Storage Spaces. Fire Safety Science