Fall Hazard Prevention At Workplace: A Study

Volume 3, Issue 2, April – June 20

Fall Hazard Prevention: A Study

Md. Aftab

B.Sc, PDIS and working as Safety Professional

Email id: md.aftab@outlook.in

1. Anatomy of fall

We have all heard the expression – ‘it’s not the fall that’s hurts but the sudden stop at the end’. Think of a fall as “… a sudden, unanticipated descent in space driven by gravity”. Even though this cannot sound excessive, the consequences are regularly disabling – or deadly. It takes most people about 1/3 of a second to become aware of a fall. It takes every other 1/3 of a second for the frame to react. A person body can fall up to approx. 2.13 meter in 2/3 of a second.

Falls: Falls always account for the finest quantity of fatalities inside the creation industry each year.

In 2004, As per Bureau of Labor Statistics (BLS), Total 1224 workplace facilities occurred due to fall. Similarly, the difficulty and price of taking care of accidents associated with falls is an emotional and monetary burden for workers and the complete creation enterprise.

Events surrounding these types of injuries and fatalities involve a number of factors, including unstable working surface, misuse of fall protection equipment, and human error.

The cost of take care of accidents associated with falls is a financial burden for the whole production industry.

2. Identifying Fall Hazards:

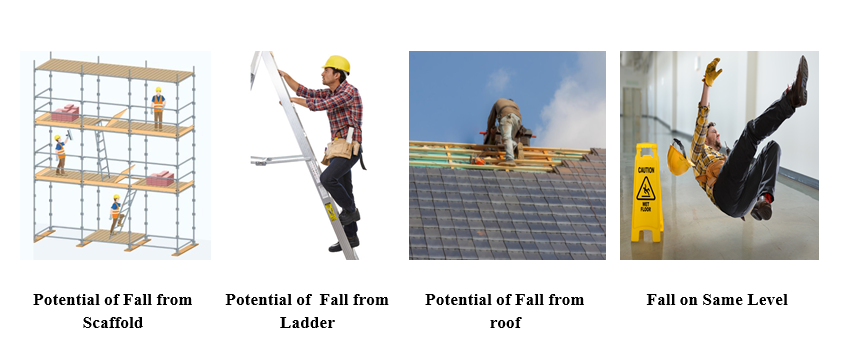

Examples of factors contributing to fall hazards:

- Scaffolds

- Ladders

- Roofs

- Fall on Same Level due to slip, Trip or Fall from other elevated work surfaces

Fig. 3

2.1 Scaffolds:

According to BLS, an average of 89 workers are killed from scaffolds each year.

Common hazards associated with all scaffolds: falls from elevation, because of loss of fall safety; the collapse of the scaffold, due to instability or overloading; being struck via falling tools, paintings substances, or debris; and electrocution, basically because of the proximity of the scaffold to overhead strength strains.

The majority of the workers injured in scaffold accidents attribute the accident to either planking or support giving way, or to the employees slipping or being struck by a falling object.

2.2 Ladders:

BLS data show that each year falls from ladders account for approximately 100 fatalities.

Factors that contribute to falls from ladders are ladder slip (top or bottom), overreaching, slipping on rung/steps, defective equipment, and improper ladder selection for a given task.

2.3 Falls from one Floor To next floor:

Falls from one Floor (level) to the next Floor (level) is a leading cause of fatalities in construction industries.

Floor holes are a common hazard. Edge protection missing is also cause of fall hazard.

It is very easy to step backwards into holes, or step into them when carrying something that blocks one’s forward view.

3. Analyze Work Area

Analyzing work area for Potential source of fall hazards may include:

- Reviewing blueprints before work begins

- Anticipating upcoming fall hazards as proposed work activity

- Reviewing for current hazards on site

- Pre-planning for fall protection

- Walk around and look

- Analyzing the work area is another important step in fall hazard prevention.

Analyzing the work area may include: reviewing blueprints before work begins; anticipating upcoming fall hazards as work progresses; reviewing current hazards on the site, and developing a pre-planning checklist

4. Hierarchy of Fall Hazard Control

Engineer out and structural integrity

Administratively prohibit exposure

Personal protective equipment

- Prevention of falls – restraint systems

- Personal fall arrest/positioning device systems

Elimination of fall hazards through engineering controls is the first and best line of defense against falls from heights. This requires a careful assessment of the workplace and the work process itself.

The prevention of fall hazards through administrative controls is the second line of defense when fall hazards cannot be entirely eliminated. This involves making changes to the workplace to preclude the need to rely on the employee’s behavior, and personal protective equipment to prevent falls.

Control of falls with personal protective equipment is the last line of defense. It should be considered only after determining that the fall hazard cannot be eliminated or prevented.

It can not to prevent to person falling but severity of harm will be reduce or minimize therefore risk will be control upto Tolerable level.

5. Controlled Access Zone Systems:

A work area distinctive and honestly marked wherein certain kinds of paintings (inclusive of overhand bricklaying) can also take vicinity without the usage of traditional fall protection structures – guardrail, non-public arrest or protection internet – to defend the employees running within the zone

Controlled access zones are used to keep out workers other than those authorized to enter areas from which guardrails have been removed. Controlled access zones, when created to limit entrance to areas where leading edge work and other operations are taking place, must be define by a control line or by any other means that restrict access.

6. Summary:

Fall hazard is major potential source of Accident at work place. There may be several sources such as floor opening, loose material in access, uneven surface, use of defective ladder, tools, railing missing of stair case, poor method of work, Poor skill etc results of personnel injury or fatality. Fall hazard can be control through hazard control method and effective implementation of Safety Management system. Proactive approach such as JSA, HIRA is best method to identify hazard and ensuring adequate control measure to control fall related workplace risk. Use suitable Tools and equipments; don’t use defective components in Scaffold to ensure scaffold safe. Need to carry out close monitoring to prevent unsafe practices and ensure adequate fall protection during working in elevated area or at height. Floor should free from any slippery material to prevent person slipping and falling.

Reference:

- OHSA, BLS

- Safety Management system in construction industries, Shahnawaz Rampuri, IJSEI, International Journal of Institution of Safety Engineers (India) Volume 1, Issue 1, Jan-Mar 2018

- ISEI Manual