Hazardous Energy Isolation Procedures in Industries

Volume 3, Issue 4, October – December 20

Hazardous Energy Isolation Procedures in Industries

Shahnawaz Rampuri

Email id: shahnawaz.rampuri2@gmail.com

Abstract

Energy is major parameter to operate equipments and run process facility. Energy is very helpful and profitable for human life as well as industries. Energy sources will be harmful, if not follow the effective and safe procedure to perform maintenance or servicing activity of any equipments, system at workplace and it can results orgnisation loss in term of personnel injury, damage to equipment or any harm. Such organisation loss occurs due to sudden release of energy and expose to personnel or equipments. Energy sudden release or machinery started and results accident due to ineffective method used to isolate energy or working on any equipments or system without isolating to energy sources. This Paper is very helpful to know about energized equipments and safe method to work on energized equipments or System. It will help to prevent accident that occurs due to sudden release of energy or startup machinery. In this paper energy is categorized and effective isolation method is identified to complete maintenance or service like activity safely.

Keyword: Energy Isolation, Type of Energy, Risk from sudden energy release, Risk mitigation, Lock out-Tag Out (LOTO) Procedure, Key error

Objective:

- Isolating energy sources to make equipment safe for maintenance or servicing like activity.

- To prevent unexpected startup of the machines or equipment, or release of stored energy that have potential to cause harm.

- To ensure effective & safe method for energy isolation.

- Ensuring effective compliance of implementation of lockout & Tag out System.

- To Prevent Accident that occur due to hazardous energy source.

- Increasing organization reputation and safety performance.

1. Introduction

In Industries, Every year several accidents occur due to unexpected startup of the machines or equipment, or release of stored energy. Majority of such accident occurs during maintenance or servicing activity. Electricity, pressure, Steam, chemical are few sources of energy that can harm to personnel or organization in case of sudden release or unexpected start up machine/equipments/systems. To avoid similar accident, need to ensure compliance of Lock out/ Tag out (LOTO) system. Effective implementation of LOTO help to control risk from such energy sources that have potential to cause harm due to sudden release or start up equipment or machine. LOTO procedure Locked, isolate to energy sources and prevent accident.

Energy sources may be hazardous or non-hazardous. Hazardous energy sources have potential to cause harm to personnel or equipments or environment. Non-hazardous hazardous energy sources has less or not potential to cause of any harm. Isolation require for hazardous energy sources to avoid any potential future accidents. Energy sources may be Process fluids, Hydraulic, Pneumatic, Thermal, Electrical, Chemical, Mechanical systems, Radiation. Pumps, Switchboard, pressure vessel, tanks, pipelines like similar source need isolation. To save people of life during maintenance or servicing activity, this is require to follow LOTO system.

Fig. 1, LOTO

2. Terms & Definition

Hazardous Energy: Energy that have potential to cause harm to people or equipments or environment or combination of these.

Energy Isolation: Disconnect to energy sources completely to perform maintenance or servicing like activity for preventing accident.

LOTO: Lock out-Tag out is a effective procedure use to ensure safety of personnel and equipments during working on machine or equipments. It ensure that dangerous machines is shut off completely and not be started prior the completion of maintenance or servicing activity.

De-Energisation: Process that is used to disconnect energy source and isolate to system for preventing sudden release of energy or start up machine

Energisation: Process to remove Isolation and connect to energy sources. In simple, this is defined as supply of energy in system to equipment or system.

3. Hazardous Energy sources classification and associated potential Risk

Hazardous energy sources can be classify on based on their nature and Following are few energy sources and their associated potential risk

3.1 Electrical Energy: Associated potential risk may beElectric shock, Electrical burn, Electrical fires or Fall of person. Fall can occur whenever person sustain electrical shock

3.2 Mechanical Energy: Crushing, Shearing, drawing-in or trapping hazard, cutting or severing hazard, impact hazard, entanglement hazard, stabbing or puncture hazard, friction or abrasion hazard are few hazard related to mechanical energy sources

3.3 Pressure Energy: Damage to body parts partially or fully, damage to other equipment or system of nearby area due to sudden release of extreme pressure.

3.3.1 Hydraulic energy: Hydraulic energy can create Cut, Bruises, entanglement like injury.

3.3.2 Steam Energy: Such energy can results burns, damage to skin or any body parts or damage to nearby equipments.

3.3.3 Pneumatic energy: Such energy may cause of eye injury due to sudden release of pressure or blown debris, skin abrasion, unexpected start of machine or machine components due to pneumatic pressure results lacerations, crushing, pinching, or amputation

3.4 Water: Risk associated with water can be person drowning, fall of person or damage to equipment.

3.5 Chemicals: Chemical can results fire, harm to personnel Health, harm to Environment.

3.6 Radiation: Effect of radiation depend upon their types, exposure duration and radiation capacity. Non-ionization radiation is less danger than ionizing. Radiation effect may be acute or chronic. Radiation can damage to blood cell, blood vessel, effect to skin, damage to tissue, risk of cancer, risk of genetic defect etc.

4. Energy and their potential sources in industries

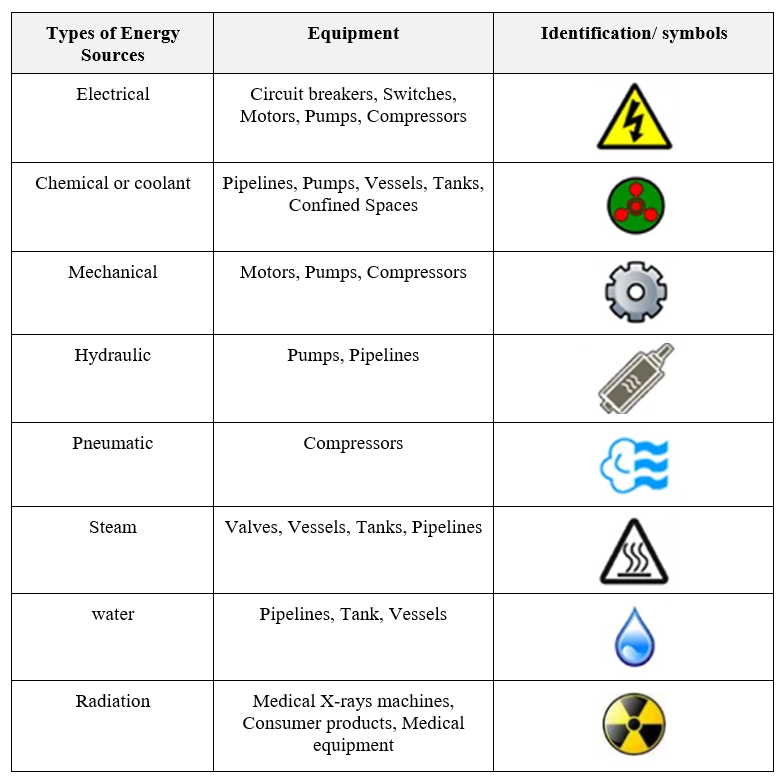

Table 4.1, Energy and their potential sources

5. Purpose of Lock out-Tag out (LOTO)

Purpose to use Lock out-Tag out (LOTO) system is to prevent accident that occur from sudden release of hazardous energy or startup machinery. LOTO protects to personnel and equipment from hazardous energy that release during maintenance or servicing equipment or system. Ineffective or no use of LOTO procedures can results organizational harm in term of fatality, injury or equipment damage or environment damage. In Industries, Time to time require to conduct maintenance or servicing activity of electrical equipment, Compressor, pipeline, mechanical equipment and these equipments have potential to release sudden energy which can be lead to cause of accident, So LOTO system implement to control risk from such energy sources that is associated with equipment and system and their hazardous nature. In simple this can be say that To save people life from sudden energy release or start up machinery, this is require to follow LOTO system.

6. Procedure of Lock out-Tag out (LOTO)

Effective LOTO procedure always help to control risk associated with hazardous energy sources and prevent accident during maintenance or servicing like activity. Below is step-by-step procedure for Effective LOTO implementation

Identify Types of Energy: Firstly need to identify types of used energy, their potential risk and available control devices.

Personnel competency: Ensure that engage personnel in job has knowledge of LOTO apply

Notify to Employees: All affected employees must be notify proactively. Here effected employees means those are associated with this equipments or working nearby or will perform task and area owner.

Turn-off all operating controls: Turn off to all Operating Control panel.

Locate all energy sources: Locate to all energy sources.

Isolate to energy Sources: Isolate to all energy sources through blocking, bleeding and through valve or other means.

Remove stored energy: Check and remove to residual energy from equipment or system where work is planned.

Locking: Lock-to all switches and energy control panel in OFF and Safe Position

Test: Test to equipment or system and ensure that no one can hurt or no one can activate to energy supply

Tag: Display Tag on isolation points.

Task: Start the work.

Before starting work, work permit compliance must be ensure, Take work permit from respective area in-charge or authorized personnel, check employees knowledge, their skill about to LOTO and respective work safety that is to be started. Whenever work finish, Notify to all effected employees before removing lock. Each Lock-out device must be removed by the person who put it on. Before re-starting to equipment check all applicable safety requirements and re-start to machinery or equipment after getting final confirmation from respective department or personnel. Few below given important factor must be remember and ensure their effectiveness for LOTO performance to control hazardous energy

- Each person is afforded individual protection.

- Hold Tag properly filled and attached to all locks

- Each lock is numbered & keyed uniquely (No key duplicates)

- Locks must be color coded; Red, Blue, Yellow and Black.

- Ensure that equipment cannot be moved to “on” or open position.

- All lock out Boxes shall be numbered.

- Work Permit System.

- Isolation, Lockout and Use of Hold Tags.

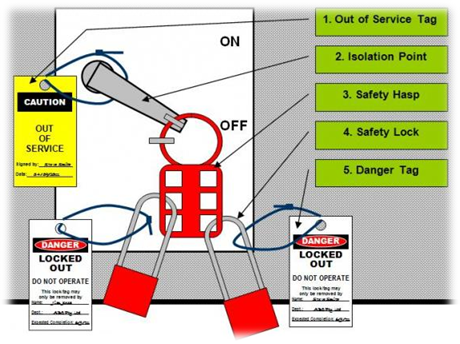

Fig. 2, LOTO Procedure

7. How to Prevent Key error to avoid Accident

Key error may be results accident. There may be several causes of key errors during LOTO procedure implementation and if any key error presence then it may results accident. Before starting on equipment or system, Personnel adopt short cut or start work without LOTO can lead to cause of accident. If equipment is not locked, then other personnel can start to equipments. Similarly if power sources disconnected, equipment locked and residual energy not remove then in this stored residual energy can also results accident. Below are few methods to avoid key error during hazardous energy isolation and complete work safely.

Stop to equipment: The main purpose of LOTO is remove hazardous energy sources to stop to equipment, there is planned to work on. So ensure equipment is completely stop or not.

Disconnect to power source: Only Switch off to equipment is not enough, therefore power source must be removed before starting to work. In case of any incident, equipment can be started suddenly

Remove to residual energy: After switching off and disconnecting to energy sources, residual or charged energy remains, so need to check and this must be remove. In Case of not removing to residual energy can results accident.

Test equipment: Test to equipment after de-energized that it cannot be activated or started.

Prevent to unexpected starting: Ensure that no one can be activate to equipment or system during work. Main purpose of Locking under LOTO is to prevent anyone from unexpectedly activating to equipment.

Clear to area before restarting: Before Re-starting to equipment after maintenance or servicing, ensure all personnel are cleared from the area

Follow proper procedure: To complete Job Safely, follow LOTO procedures properly. Don’t take short cut and assign job to competent personnel only.

Display Tag: Tag must be display clearly with identification Numbers.

Training: All engage personnel on equipment must be train and they should know the details procedure to apply LOTO

Apart from this, ensure effective implementation of work permit and carry out close supervision through qualified and skill personnel to prevent human error and ensure necessary requirements of LOTO.

8. Lock out-Tag out (LOTO) System Checklist

Checklist help to ensure basis requirement that require for LOTO. Below is check basis

| Check Points | Status | Remark | |

|---|---|---|---|

| Yes | No | ||

| Before Apply LOTO energy identify& Isolation Point identify | |||

| Have effected employees notify/inform before apply LOTO | |||

| Do the employees Trained for LOTO procedure, authorization card available and able to apply? | |||

| Are all existing installed isolation tags and locks are properly recorded in LOTO log register for record and monitoring purposes? | |||

| Does the contractor or respective department personnel has adequate LOCK, Tag, Testing devices and good working condition? | |||

| Do the maintenance personnel conducted and attended tool box talks in relation to LOTO procedure and record it? | |||

| Have operations (Isolation Technician) isolated the equipment by placing their lock and tag on first? | |||

| Has the isolation been checked (tested) to confirm it is correct? | |||

| Do the tags give information regarding the isolation | |||

| Have all disciplines involved placed their locks and tags on to the isolation | |||

| Has the isolation been completed to the correct standard | |||

| If the answer to the above question is no, has a risk Assessment been completed for this type of isolation | |||

| Does this isolation involve group lockout/tag out? | |||

| Is a multi-hasp or key lock box being used | |||

| If a key box, are the locks applied correctly and operations (Isolation Technician) key locked away safely | |||

| Did the Isolation Technician verify that the equipment was de-energized | |||

| Did the Isolation Technician follow the lockout/tag out process | |||

| Does the lockout/tag out put in place adequately protect workers | |||

| Did the isolation get appropriately reviewed with all personnel involved? | |||

| Other observation, If any |

9. Conclusion:

Lock out-Tag out (LOTO) is effective safety procedures that help to prevent industrial accident. This is hazardous energy control method used to ensure safety for people or machinery during servicing or maintenance activity. Hazardous energy may be in the form of electrical, hydraulic, pneumatic, kinetic, potential, thermal, chemical, and radiation. During working on energized equipment without follow LOTO procedure, sudden release of energy or startup machinery can results accident. Therefore working on energized equipments or system, need to take adequate precautionary measure to avoid untoward happening. In industries many accident happen due to sudden start up machinery or equipments or release of energy and such methods help to eliminate or reduce risk related to energy. In LOTO power disconnected, lock to system, Tag out, test and then start the work. After completion work, remove the tag, remove the lock through each individual that were engage in job and resume the power source to ensure all require safety measure.

References:

- ISEI manuals

- Study of Machinery Safety in Industries: A review, Mr. Alok Pathak, Volume 2, Issue 1, Jan-March.19, Page 08-12, International Journal of Institution of Safety Engineers (India)

- Effective Handling of Fluids and Liquid Metals using IoT, Praveen Sankarasubramanian, Volume 3, Issue 1, Jan-March 20, International Journal of Institution of Safety Engineers (India)

- RNSN Seriate Safety Manual

- Study of Hazard Identification & Risk Assessment Techniques, Volume 1, Issue 3, Jul-Sept. 18, Page 01-05, International Journal of Institution of Safety Engineers (India)

- Safety Hazardous Lockout Tagout System in Automobile Industry, A.Venkatesan1 , R.Hariharan2 , R.Prabhu3, I.Sirajudeen4 , M.S.Santhosh5, International Journal of Innovative Research in Science, Engineering and Technology, Vol. 6, Issue 8, May 2017

- Bulzacchelli MT, Vernick JS, Webster DW, Lees PS. Effects of the Occupational Safety and Health Administration’s control of hazardous energy (lockout/tagout) standard on rates of machinery-related fatal occupational injury. Inj Prev 2007; 13:334–338.

- Behnam Emami-Mehrgani, SylvieNadeau, Jean-Pierre Kenne´. Lockout/tagout and operational risks in the production control of manufacturing systems with passive redundancy [J]. Int. J. Production Economics 2011;132:165-173.