Portable Hand Tools Safety

Volume 3, Issue 4, October – December 20

Portable Hand Tools Safety

1Annapurna Adiley

Email id: reshu.adiley@gmail.com

2Shahnawaz Rampuri

Email id: shahnawaz.rampuri2@gmail.com

Abstract

Portable hand Tools is essential mechanism to complete Operation, maintenance & construction related activities of industries. Portable tools use in industries as well as home to complete work easily and safely. Tools may be different types and as per their application tools has been to used. Portable hand tools may be powered manually and powered with the help of energy sources. Tools operated with the help of energy sources have high potential of harm respect to powered manually. In industries several accidents occur regularly due to use of non-standard or defective tool and unsafe method use to operate such tools. Tools related accident results pain, suffering, work delay and several others harm. Study on Portable hand tool related accident has been done to know major cause of hand tool related accident and how to such accident can be prevented. Therefore, this paper is very helpful to evaluate tool related risk and reducing to such risk. A study also conducted to collect data from few industries to know actual cause of accident and how can such accidents can be prevented.

Key word: Portable hand Tool Safety, Hazard related to Portable hand tool, Potential Risk, Risk control measure.

Objective: Objective to conduct study and publish this paper is control portable hand Tools related Accident for preventing organizational harm, increase organizational reputation, increasing organizational employee’s morale and avoid work delay.

1. Introduction

In Industries, Portable hand tools have potential sources of harm, if not follow to safety rules during using. Portable hand tools are important Tools that are used regularly in industries. Such Tools are also use in home. Portable hand tools operated manually as well as with the help of energy sources. Wrenches, pliers, cutters, files, striking tools, struck or hammered tools, vises, clamps, screwdrivers, snips, saws, drills, knives are few examples of manual operated tools without aid of Power (Powered manually) and similarly grinding machine, drilling machine, tappers, fastener drivers’ machine are few examples of power operated hand tools (Operated with the help of energy sources. Power hand tolls are very helpful to reduce time and complete task easily. Different tools have different application and as per application such tool has been used. To use tool, this is required to ensure all safety parameter such as tool quality, operating method, potential risk minimization and training for operator to avoid any potential future harm.

Power operated Tools means, such hand tools that are operated with the help of energy sources. Power Operated hand tolls have more potential of accident respect to manually powered. Tools may be categories into Two ways, Tools operated with help of Power (energy sources) is known as power tools & Tools operated manually (Powered manually) without energy sources is known as Non-Power Tools. In simple way we can say that Non- power hand tools, powered manually and power hand tools, Powered with the help of energy source. There may be several types of Power hand tools on based of power/energy sources and power sources may be Pneumatic, Liquid Fuel, Hydraulic and electrical.

Fig. 1 (a), Portable Power Hand Tools

Fig. 1 (b), Portable Hand Tools powered manually

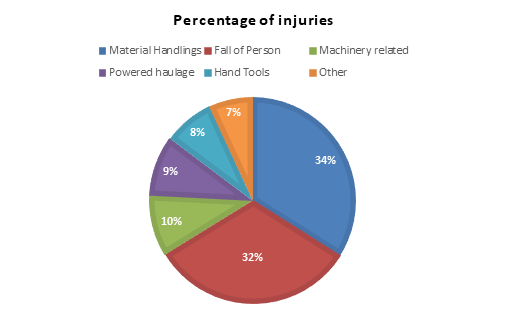

Article published on UKESSAYS website to mention reference of BLS and OSHA, 712 death were occurred in year 2012 due to contact with hand and power tools, 25.5 Non-fatal injuries were occurred in every Ten thousand workers due to using hand and power Tools. Survey was conducted to collect data of from emergency room (EC), survey show that 400,000 visited to EC due to hand and power tools related accident. As per Bureau of Labor Statistics (BLS), one out of every 10-construction industry employees is injured annually by power tools. Report Published on CDC website on reference of NIOSH, 8 Percent accident were occurred in mining industries due to using hand Tools in 2011 (Fig.2).

Fig. 2, Sources, CDC, NIOSH

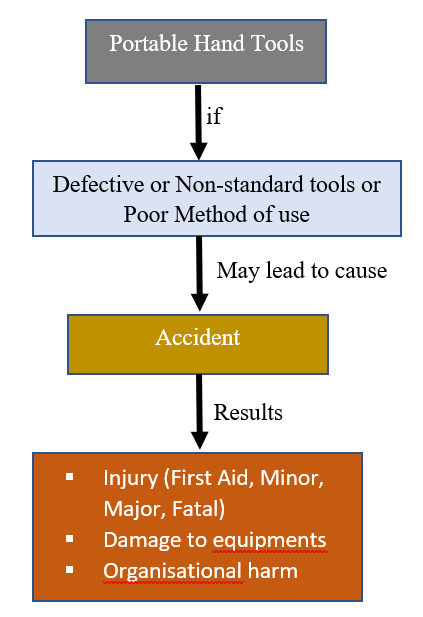

2. Cause of Accident & Potential injury

There may be several reason of accident during using Portable Power hands tools and major causes may be use of defective or non-standard tools or Tool operated by less experienced personnel (Not or partially trained). Person who using Portable hand tools may be expose to hazard of flying and splashing objects, contact with rotating parts or sharp edges, falling or to harmful mists, dusts, fumes, gases. Exposure to person may be danger parts or energy sources of power operated hand tools. Cause of exposure of potential hazard may be use of defective tools or human error. Human error may be Non-use of appropriate personal protective equipment (PPE’s) or over speeding or poor concentration of work or not follow safety rules as per Tool manufacturer recommendation or not follow to Safe operating procedures. Cause of human error may be Poor enforcement of Safety rules, heavy work load, Stress, Tool operated by less experienced personnel, poor supervision, or employee health Issue. Potential hazard lead to cause of accident and accidents results cut injury, abrasion injury, bruises injury, crushed injury, electrical shock, Person fall, injury due to hit by object and injury due to not fulfilling ergonomical factors. In few cases, Portable hand tools related accidents results fatal accident. Portable Power hand Tools can results of Fire and electrocution also Fig. (3)

Fig. 3, Portable hand tools related accident

3. Study Method

Study is conducted to collect data from seven industries including Construction Industries. Data of accidents are collected only from Portable hand tools related accident. Accidents has been categorized on based on injury (Fig., 5) and cause wise (Fig., 4).Study has been conducted as per below steps

- Data collection: Portable hand tools related Accidents data collected from different resources including Safety Professional of respective industries.

- Study on accident

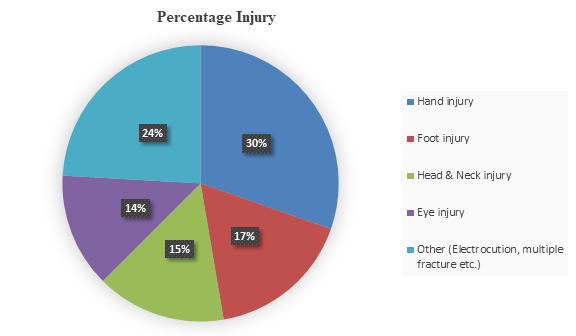

- Injury classification human body parts wise

- Cause wise classification

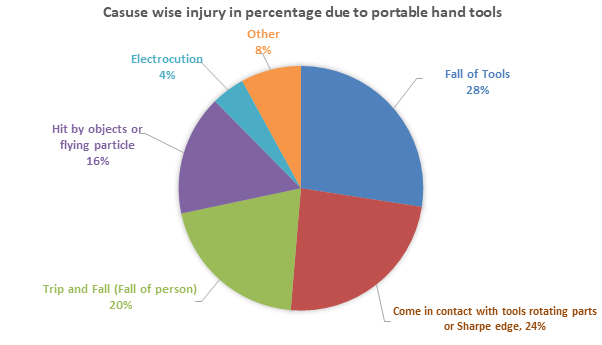

4. Study of Portable Hand Tools related accident:

A study conducted to collect data of accident related to portable hand tools from seven industries including three EPC project. These data were collected from different sources including respective industries safety professional and found that total 113 hand tools related accident were occurred during 2018-19 (Two year) in which 84 were first aid Nature (resume duty on same day), 17 were Major injury (unable to resume duty within Two day) and 2 was fatal.73 accident were recorded in Three construction industries and 40 were Reported in Process Industries. Two Fatal accidents were occurred in EPC industries, 1 due to hit by breakage grinding wheel and second due to electrocution.

Fig. (4), Study by ISEI in year 2018-19 to collect Portable Hand Tools related accident

Fig. 5, Sources, ISEI Study 18-19, Body part wise injury

5. Safety Measure for Portable hand Tools

Portable hand tools have high potential of risk, if not follow to safety rules. Such risk can result accident. Following are few safety majors that help to control hand tools related risk

- Never use defective and non-standard tools. Inspect to tools before using.

- Ensure guard on rotating parts of Portable power tools.

- All operating and control switches of tool must be in good working condition.

- Disconnect the power source, when tool is not in use.

- Don’t allow to unauthorize person in work area.

- Before using check to tools. Avoid accidental starting.

- Follow to manufacturer recommendation guidelines. Tools must be fulfill to ergonomical factor.

- Remove all damage Portable hand tools.

- Store tools to suitable and safe place. Avoid to keep loose tools at work place.

- Don’t carry Tools by cord or hose.

- Avoid to hold work piece material by hand, always use clamps or vise to secure work pieces. Use your both hand for your safety and using tool safely.

- Always use Tool bag to carry tools at height. Don’t keep loose tools in elevated area to avoid fall.

- Avoid to use loose cloth or Jewelry, ring during using Portable power hand tools

- Power routed through adequate rating of ELCB for Portable Power tools.

- Use suitable Personnel Protective equipments (PPE’s).

- Tools must be operated by trained personnel.

- Carry out close supervision through competent personnel during work to prevent human error.

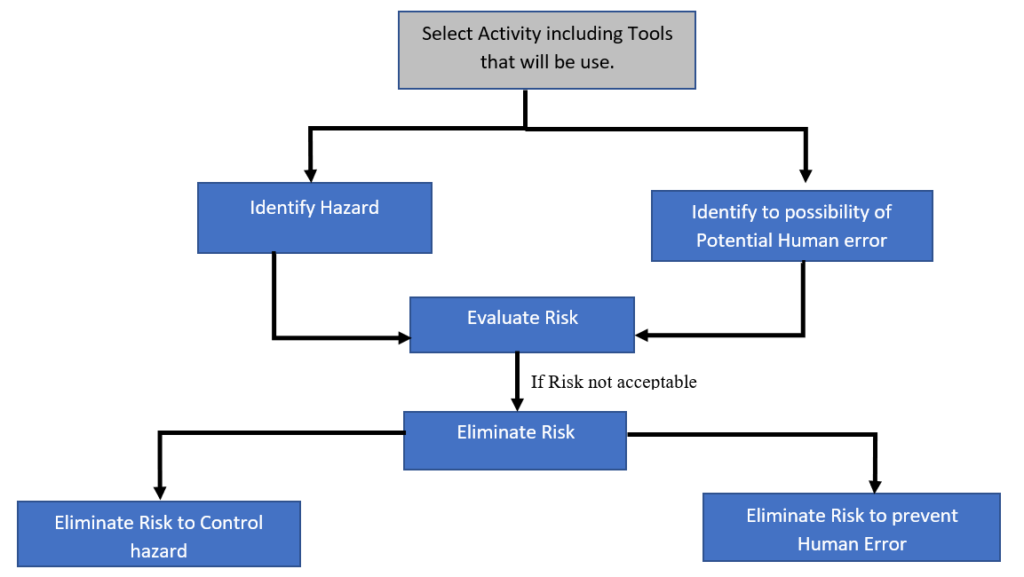

6. Risk Control during Tools using

To control Tools related accident, need to control Tools related Risk. To control Tool Related Risk, need to select activity and Tools that will be use and identify the potential sources of harm or situation including human error and based on this, need to control hazard and prevent to human error to avoid any future accident Fig. (6)

Fig. 6, Tools related Risk Control

7. Conclusion

As per study, Portable Hand tools related accident occurred due to poor method of tools using or defective tools used. Person used poor method due to poor skill about the job or tool operating, work load or health issue. As per study, Power operated (operated by energy sources) portable hand tools are more dangerous than Powered manually Tools. Power operated hand tools have potential risk to cause of electrocution and fire also. As based on ISEI study, found that majority of accidents occurred due to Fall hazard (fall of Tools or Fall of person) and second cause of accidents were due to contact with hazardous parts of tools including rotating parts, sharp edges. Majority of Injuries were associated with Hand and Foot injury. Apart from this Eye injury, Face and neck injury also occurred during accidents related to Portable hand Tools using.

Portable hand tools related accident can be prevented to use standard tools, avoid to use defective tools, check to tools before using, disconnect to power sources when tools is not in use, avoid to keep tools in elevated area where are potential of tools falling, Tools must be use by Trained personnel. Administrative control measure plays important role to control tools related risk. Effective enforcement of safety rules and close supervision helps to prevent human error. Follow manufacturer recommendation during using portable hand tools to avoid any hand tools related accident.

References:

- Study of Machinery Safety in Industries: A review, Volume 2, Issue 1, Jan-March.19, Page 08-12, International Journal of Institution of Safety Engineers (India)

- https://www.ukessays.com/essays/employment/hand-and-power-tools-injuries.php

- https://www.legalmatch.com/law-library/article/work-tools-accident-statistics.html

- Hazard control method in Construction Industries, Mrs. Annapurna Adiley, Volume 3, Issue 1, Jan-March 20, International Journal of Institution of Safety Engineers (India)

- https://www.cdc.gov/niosh/mining/works/statistics/factsheets/07sgo.html

- Ergonomics considerations in hand and wrist tendinitis, Journal of Hand Surgery Vol. 12, Issue 5