Safe Critical Lifting Practices Followed During The Structural Erection

Volume 7, Issue 1, January – March 2024

Safe Critical Lifting Practices Followed During The Structural Erection

Viswanadha Appala Narasimha Murthy

Safety Professional, M.Tech, PDIS

Email id: murthyehs@gmail.com

Abstract

The study has been carried & prepared for the execution of MMRDA MUMBAI Project, being executed by J. KUMAR and this is a guideline for all employees of J. KUMAR as well as its subcontractors for ensuring minimum risk to environment, property and human beings working on site or using the roads where construction activity is in progress. This study enables the control of Environment, Health & Safety risks and helps in the continual improvement of its SHE performance.

I. Introduction

An assessment has been made of the safe critical lifting operations performed during the structural erection activity. The study was carried out in the metro rail project to emphasize the safe control measures during critical activity.

2. General

When using lifting equipment:

- Know the correct weight of the load before it is lifted.

- Do not operate if you are not trained.

- Never overload when lifting materials. Keep to its safe working load (SWL)

- Examine lifting equipment before use. Don’t lift if the load is not secured.

- Do not stand or walk under a suspended load.

- Crane operators found tempering with any safety devices shall be dismissed from site immediately.

2.1 Erection Work – General

- The erection work plan and procedure shall be checked thoroughly by the Contractor’s construction supervisor.

- Warning signs of “NO ENTRY” and safety ropes shall be provided by work supervisors.

- The strength of the road on the route of the crane shall be checked by the Engineer. The supervisor shall check for any obstacles on the route of the crane.

- All cranes, lifting gears and winches shall be tested and inspected half yearly, the valid certificate shall be displayed on the lifting machines. Cranes or winches shall be locked or braked when not in operation.

- Subcontractors performing work requiring daily/regular lifting operations—such as piling, decking, erection of major plant– shall provide a person competent in lifting operations who will be appointed by J. Kumar CRTG(JV) using Appointment Letter (see Appendix) as the lifting supervisor for the subcontractor’s work.

- The lifting supervisor will fill out and submit to the Station Manager/ Safety Engineer a checklist before lifting operations is carried out.

2.2 Erection by Crane

- Lifting work shall begin only after confirming by preliminary check that the crane is set up satisfactorily. The crane access and its position must be checked for stability to prevent crane from toppling. Site Engineer must check and ensure that the load bearing of the ground is adequate for the lifting work. If the crane is positioned for a long period of time, the appointed Site Engineer must carry out daily check to ensure no deterioration of the ground condition.

- The crane shall be secured horizontally, and steel plates or square timbers shall be placed under the outriggers firmly, and then secured with knock pins after being set in position.

- The operator shall not leave the crane or winch during lifting work.

- The inclined angle of the boom during operation shall not exceed the range of 30 80 degrees unless otherwise specified for the machinery. When using the jib its length must be minimized. An angle indicator shall be provided for the crane operator to visually check the boom angle. Crane booms shall be lowered to the ground level, and the hook shall be secured to the specified position when the crane is not in use.

- When moving cranes, the boom must be lowered, and a boom walker must be provided in addition to the crane operator. Crane booms must not be operated closer than 2m to any overhead line or electric transmission wire. When it is necessary to operate closer than 2m, special permission must be secured from the Employer’s representative and arrangements made to cover or reenergize the circuit line.

- Only authorized persons with a license/training shall be permitted to operate the crane or do slinging for lifting equipment.

- The strength of the ground where the crane is to be placed shall be examined. If necessary, reinforcements, such as installation of steel plate shall be arranged.

- The foreman and signalman shall be assigned for each erection work under an operating system established for the work. During crane operations, they should stand in a position that allows them to observe the loading operation and be clearly visible to the crane operator.A uniform signal system shall be used for flags, transceivers or hands for signaling.

- The capacity of the crane to be used for erection shall be determined after careful consideration.

- Total lifting weights and the center of gravity of equipment to be erected shall be carefully re-checked before commencing erection work.

- Load indicators shall be installed on the cranes.

- Before starting the work, the condition and functioning of the brakes, limit switches, over hoist prevention devices, wire ropes and lifting devices shall be checked and inspected and the crane shall be operated on a trial basis without a load. As a preliminary check, the equipment shall be lifted and held 10cm from the ground. In this state all elements shall be checked and inspected to see if they are functioning properly. A lifting job shall be halted immediately if risks are detected.

- Lifting work shall not be carried out during bad weather, such as strong winds or heavy rains.

- Crane shall never be loaded more than the manufacturer’s stipulated rating. Lifting load for each crane shall be controlled within 90% of the maximum lifting load (to read from load indicator). The lifting load shall include dead load of lifting, hook, rope, etc.

- In case of the lifting work, the operation shall be carefully supervised to prevent hasty lifting, prolonged suspensions and lifting beyond the limit. Abrupt lifting and stopping shall be prohibited.

- Simultaneous rotation and sudden lifting or rotation and boom movement shall be prohibited.

- The boom shall be slowly rotated so as not to produce centrifugal forces on equipment or materials being lifted.

- Workers shall be forbidden to ride on lifted equipment or material when lifting or swinging is taking place.

- The crane’s wire rope shall be rolled up entirely after the work is completed.

- Safe Working Load (SWL) for the crane shall be conspicuously displayed on the crane body.

- Crane load chart shall be displayed inside the operator’s cabin in the language understood by the operator.

- The crane shall have a valid operating license issued by the competent authority. The validity of the license shall be six months & The lifting hooks shall be provided with a safety catch.

2.3 Girder Launching

Fig. 1

J. Kumar CRTG (JV). will take utmost precaution during planning, establishing casting yard, casting segments, transporting segments, fabrication and erection of launching girders, launching of segments, pre-stressing, auto launching of girders and dismantling of launching girders.

J. Kumar CRTG (JV) will prepare a comprehensive method statement for the launching operation, adhering to the SHE conditions.

- Necessary working platforms and fall protection anchorage arrangement shall be provided in the launching girder itself,

- Provisions for mounting light fittings shall also be made available in the launching girder, adequate lighting at all-time shall be ensured in the entire area of operation.

- Launching Girder shall be tested by competent person and certificate will be issued for use.

- Riding on segment will not be allowed during launching.

- Unauthorized entry will be restricted in segment lifting and fixing area.

- Only trained manpower shall be allowed to work in launching operation.

- Double Lanyard Full Body safety Harness shall be provided to all workers working at Height.

- No Loose material shall be allowed to store on Segment it can be cause of material falling.

- Regular Training to all workers will be ensured by SHE Dept.

2.4 TRAFFIC

2.4.1 General

J. KUMAR CRTG (JV) will ensure the safe and efficient movement of traffic and to ensure the safety of workmen at construction sites. A high visibility jacket with reflective tape should be provided to all construction workers to protect them from speeding vehicles.

Only authorized personnel registered with J KUMAR CRTG (JV) are permitted to operate motorized equipment. Operators shall have a valid operator’s license. They shall be seated inside the vehicle body when in transit.

2.4.2 Parking

All vehicles shall be parked in the area designated by J. KUMAR CRTG (JV), except vehicles in use for construction work. Narrow roads are to be always opened for access.

Motor vehicles and other mobile equipment shall not be parked adjacent to fire hydrants, firefighting equipment, building exits, walkways, etc. In principle, all private cars (petrol driven) shall be forbidden from the construction area.

2.4.3 Trucks

Trucks and other transport equipment shall be constructed to prevent materials from falling off onto the road. Any materials displaced shall be removed from the site immediately.

2.4.4 Route to Site

All persons engaged in construction works or visitors shall use the designated entrances only and should not walk through or around the existing plant at any time.

2.4.5 Legal permission

- In all cases, J. KUMAR CRTG (JV) will employ proper precautions. Wherever operations undertaken are likely to interfere with public traffic, specific traffic management plans shall be drawn up and implemented by J. KUMAR CRTG(JV) in consultation with the approval of local police authorities and/or the concerned metropolitan / civil authorities.

- Such traffic management plans shall include provision for traffic diversion and selection of alternative routes for transport of equipment. If necessary, J. KUMAR CRTG(JV) will carry out road widening before commencement of Works to accommodate the extra load.

- In work zones, traffic control devices include signs, delineators, barricades, cones, pylons, pavement markings and flashing lights.

- Road construction and maintenance signs will be used in accordance with the same three major categories as other traffic signs, namely Regulatory Signs, Warning Signs, and Direction (or guidelines) Signs.

It is essential, therefore, that they are used only after consulting the local police and traffic authorities. Regulatory signs

Regulatory signs impose legal restrictions on all traffic. To avoid any legal ramifications, it is essential that they be used only after consulting the police and traffic authorities.

2.4.6 Speed Limit

All drivers shall obey the speed limit which is 20km per hour unless otherwise specified by signs or boards installed by safety committee.

The basic objective of the following guidelines is to lay down procedures to be adopted by Contractor to ensure the safe and efficient movement of traffic and to ensure the safety of workmen at construction sites.

It is recommended that all construction workers wear high visibility jackets with reflective tapes since most of the work on viaducts, tunnels, and stations is either above or below the right-of-way.

- To ensure safety in construction zones, it is important to follow the following guidelines:

- Provide a clear and sufficient warning to the road user.

- Provide safe and clearly marked lanes for guiding road users.

- Provide safe and clearly marked buffer and work zones.

2.4.7 Delineators

- Traffic delineators serve two different purposes as part of a total traffic control system:

- To delineate and guide the driver to and along a safe path

- As a taper for moving traffic between lanes.

- Controlling traffic flow requires channelizing devices such as cones, traffic cylinders, tapes and drums to be placed alongside the roadway. These should normally be retro- reflectors Traffic cones and cylinders

- Traffic cones of 500mm, 750mm and 1000mm high and 300mm to 500mm in diameter or in square shape at base and are often made of plastic or rubber and normally have retro- reflectorized red and white band shall be used wherever required.

2.4.8 Traffic Drums

Drums about 800mm to 1000mm high and 300mm in diameter can be used either as channelizing or warning devices. These are highly visible, give the appearance of being formidable objects and therefore command the respect of drivers.

2.4.9 Warning Signs

All workers shall obey the street stops and warning signs. Materials hanging over the end or sides of a vehicle shall be distinguished with a red flag.

Fig. 2, Safety Signages

- Warning signs in the traffic control zone shall be utilized to warn the drivers of specific hazards that may be encountered.

- J. KUMAR will place detour signage at strategic locations and install appropriate warning signs. To minimize disruption of access to residences and business, J. KUMAR CRTG (JV) will maintain at least one entrance to a property where multiple entrances exist.

- A warning sign as given in General Instruction of contract shall be installed at all secondary road which merges with the primary road where the construction work is in progress at sufficient distance before it merges with the primary road so as to alert the road users regarding the ‘Metro Work in Progress’.

- Any materials hanging over/protruding from the chassis / body of any vehicle, especially during material handling, are to be marked with a red indicator (red light/flag) to warn road users.

2.4.10 Barricades

- A full-height fence, barriers, barricades etc. shall be erected around the site to protect the working area from the risk of accidents due to speedy vehicular movement. Same the way barricades protect the road users from danger due to construction equipment and other temporary structures.

- A tender document shall specify the dimensions, material, composition, design and other details of the barricade.

- All barricades shall be erected as per the design requirements of the Employer, numbered, painted and maintained in good condition and the Barricade in-charge maintains a barricade register on site.

- J. KUMAR CRTG(JV) will ensure that all his construction vehicles plying on public roads (like dump trucks, trailers, etc.) have proper license to ply on public roads.

2.4.11 Tow away vehicle.

J. KUMAR CRTG(JV) will make necessary arrangements keeping tow away van / manpower to tow away any breakdown vehicle in the traffic flow without losing any time at his cost.

2.4.12 Cleaning of roads

J. KUMAR CRTG(JV) will ensure the cleanliness of roads and footpaths by deploying proper manpower for the same. J. KUMAR CRTG(JV) will have to ensure proper brooming, cleaning, washing of roads and footpaths on all the time throughout the entire stretch till the currency of the contract including disposal of sweep age.

2.4.13 Lightning

Fig. 3

Lightning is nature’s worst destroyer. A typical lightning bolt contains several hundred million volts at 30,000 or more amperes.

- Lightning need not strike a person directly to be dangerous.

- Lightning can crash down from virtually clear sky.

- Stay away from open doors or windows during an electrical storm.

- Avoid using the telephone or television set and keep clear of all metal objects such as pipes and electrical appliances during a storm.

- Do not go outside.

If you find caught in a storm away from a protected building:

- Avoid tree lines.

- Stay away from unprotected storm shelters.

- Stay away from flag poles, towers, and metal fences.

- Do not wade, swim, or go boating in a thunderstorm.

- A closed automobile provides a protective metal shell.

- If caught in the open, stay low.

2.4.14 Barricading

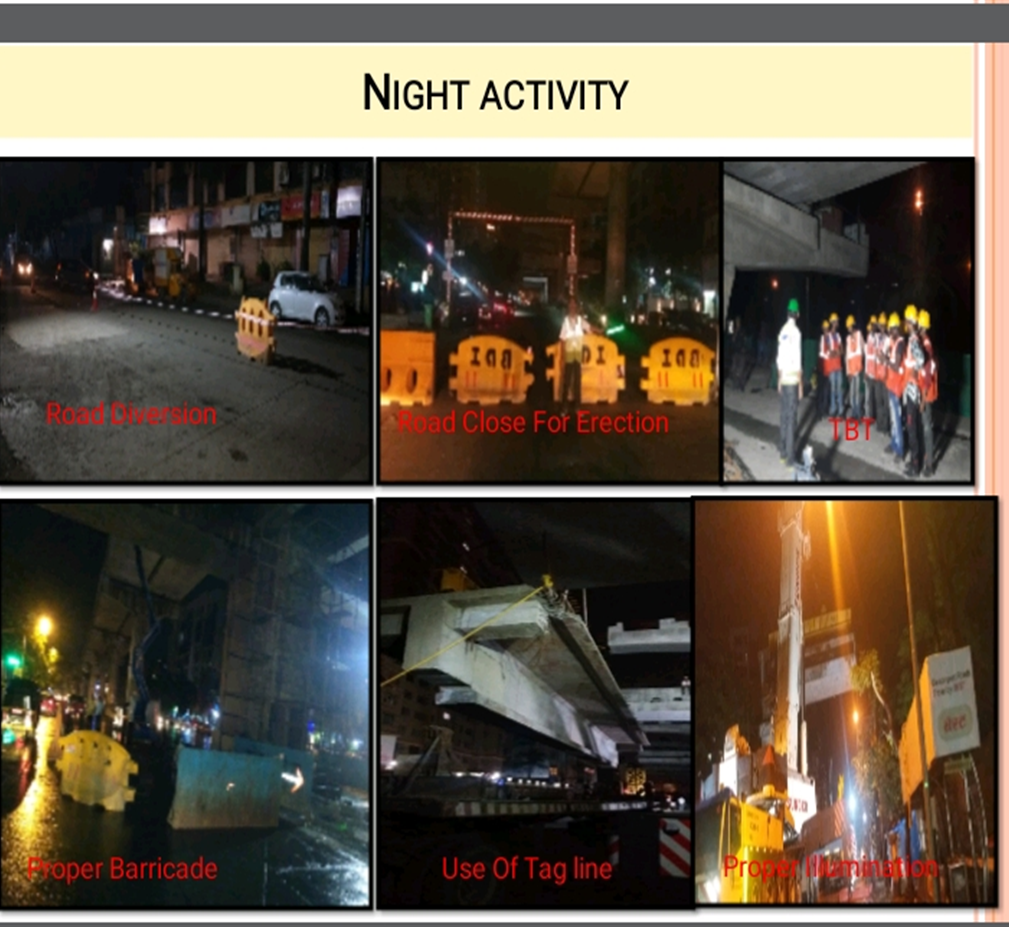

Fig.4

2.4.15 Transportation

- Loading and unloading of boards shall be done by crane.

- To prevent boards from swelling during loading and unloading, tag lines should be used.The boards shall be shifted to the desired location by dumper.

- During unloading of boards at desired area the traffic shall be restricted with the help of traffic marshals and placing traffic cones.

2.4.16 Fixing of Boards

- Proper care shall be taken during the fixing of the boards.

- A high visibility jacket with reflective tape should be provided to all construction workers.

- Anchoring of board shall be made by 25mm Dia reinforcement nails.

- Slot cuts shall be provided for anchoring one board to adjacent board.

- While manually fixing the barricading board, the area shall be covered with caution tape and traffic cones. Traffic marshal shall be available for traffic diversion.

2.17 Barricading Light

For convenience of traffic, blinker shall be provided throughout edge of the barricading board. In certain cases, blinkers are also to be provided (e.g. at important and busy intersections). Ensure that the blinkers are on. Any deviation/damaged bulb shall result in an appropriate penalty.

3. Conclusion

Safe and effective Lifting practices followed during the structure erection always help to minimize or control risk that occur during lifting job. Effective lifting practices always help to prevent accident and create safe healthy environment. Lifting activity is highly risky job and this risk can be control upto tolerable level through hazard control method including elimination, substitution, engineering control and administrative control. Effective planning, use of suitable and standard quality lifting equipment, experiences and competent team member can play vital role to prevent accident related to critical lifting operation.

References

- Safety Manual