Line of Fire ! – Protect Yourself

Volume 2, Issue 4 – 01, October-December 19

Line of Fire ! – Protect Yourself

Mr. Adil Naseer– HSE Engr.-SMISE, TechIOSH, B. Tech (M.E), NEBOSH IGC, IOSH MS,IMSInternal Auditor – ISO 9001/14001/45001 – with 08+ yrs. Experience in QHSE field, Current working at Hamad International Airport – Qatar as QHSE professional

Email id: hsefmm@gmail.com

Abstract:

Am I in the Line of Fire?

Being in the line of fire indicates that you or someone else is placed in the path of something that could cause injury or something more severe. Here are a few questions to ask yourself:

- Do I recognize if others are in my work area?

- Do I take the time before every task to check my surroundings and my equipment to determine what the safest position is?

- Do I consider myself when I think about what could go wrong with my task?

- Have I eliminated every hazard that I could?

- How many times a day do I realize I am in the line of fire?

- Did I use my Human Performance Tools?

Objective

It is important to understand what the “line of fire” is and how to avoid being in it to avoid any serious injuries.

- What is “Line of Fire”

- Common areas of concern

- Line of Fire examples

- Work activities and equipment involving line of fire

- The basic process of Line of fire.

- INTRODUCTION

WHAT IS “LINE OF FIRE”? Line of Fire, which was originally a military term, is now commonly used in industrial safety.

- Situations where workers put themselves in harm’s way by virtue of thetype of work they are carrying out.

- Lack of awareness

- Lack of education

- Hazards can be hard to recognize and can Cause injury

- Incapacitate

- In severe cases, kill the employee or co-workers.

- COMMON TARGET AREAS OF CONCERN

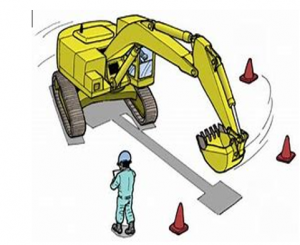

- Heavy Equipment

- Machinery

- Manufacturing

- Assembly

- Hand and Power Tools

- Material Handling

- Mobile Equipment

- LINE OF FIRE EXAMPLES

- Dangers presented by the sudden release of tension

- Gravity

- Moving machinery

- Path of travel

- Flying debris and projectiles

The line separating safety from danger is sometimes quite small. To avoid crossing that line, we must

- Always be aware of the hazards around us

- Understand the machines and operations in our work areas.

- Take the time to think about the possible consequences that may result from where we place our bodies or the actions we perform.

When we do this, we can avoid suddenly finding ourselves in the “line of fire”

“what you don’t know can hurt you”

In many years we witnessed a lot of life changing moments which resulted from not taking a few minutes to consider whether we are in the line of fire, or in the safe line of work.

We maybe in our offices doing our daily task and reports, or in our workplaces at mechanical rooms, electrical rooms, pump rooms, storage areas, or doing our daily inspections we cannot deny that there are occasion where we unconsciously place ourselves in the line of fire, perhaps because of certain external and internal factors around us. Mostly of these moments are from our human factor- the error of omission which we fail to perform a procedural step, error of commission which we perform extra steps that are incorrect or performs a step incorrectly or lack of hazard understanding. But what is line of fire in connection with our daily task?

- LINE OF FIRE

Line of fire is when we place ourselves in danger from heavy equipment, machinery, hand and power tools, material handling, mobile equipment brought about by internal and external distractions (frustrated, tired, in rush), complacency, or lack of hazard understanding.

Line of Fire is the path an object will travel and create a risk of injury.

‘You are in the line of fire when you are at risk of coming into contact with a force that will, or may hurt you’

According to “Joseph Baldwin a consultant at Baldwin EHS Consultants” Line of fire hazards are one of the most deadliest hazards found in Manufacturing and Construction, second only to Slip, Trips and Fall. Each year hundreds of workers are injured by Line of Fire accidents. Deaths from Line of Fire injuries number into the hundreds.This could be:

Approximately 27% of work place deaths are related to Line of Fire accidents in the United States of America.

| Three Mechanism of Injury | ||

|

Stored energy

– Contact with Stored energy |

|

|

Striking Hazard

– Struck by or Striking against an object – Includes falling objects |

|

|

Crushing Hazards – Caught in, on or between an object |

|

Work activities and equipment involving line of fire

- Lifting/hoisting

- Moving vehicles/heavy equipment

- Hand and power tools

- Moving parts

- Electrical equipment

- Objects with roll potential

- Objects with fall potential

- Tensioned lines and equipment

Through the years Institution of Safety Engineers (India) as an organization has been promoting safe system of work through information, instruction, training and supervision, with a collaborative effort from every Head of the department.

Being in as a member SMISE, I witnessed in my Company that most of our lost time accidents are more of behavioral aspects, which sprung from our subjective worldview of health and safety. Health and safety is not only HSEQ department responsibility it is everyone’s responsibility.

Not just one person it is EVERYONE- whether you are a Manager, an ordinary Technician or a Cleaner you have the responsibility to ensure your safety.

Institution of Safety Engineers (India) way is to be health and safety committed and honoring that commitment through continuous information, instruction, training and supervision towards good and positive health and safety culture with everyone’s collaborative effort.

Where should we go from here? We should reduce and minimize our exposure to line of fire incidents and we should be aware of the 3 major factors of every incident, accident at our workplace. These are human, organization and technical aspect.

Human Aspect: We should be aware and identify the hazard before starting the work and apply the control measures in place. If you’re in doubt, ask your Supervisor or your Engineer. Ensure you are trained of the method statement and risk assessment of the task and be fully aware of the risk involved and possible consequence that could result from what you are about to do.

Organizational aspect: Institution of Safety Engineers (India) to ensure procedures and policies are in place and are being followed, like method statement and risk assessment, standard operating procedure, COSHH assessment for chemicals, ongoing learning and training for all employees, ensuring safe workplace, daily morning briefing and tool box talk, and regular inspections and supervision.

Technical aspect: that we should always use the right tools and equipment for our job with good condition and safe to use and putting hazard signage for machinery or equipment like MEWP (mobile elevated working platform.

What should we be doing every day, as a member of Institution of Safety Engineers (India) we follow ERICP to a brighter future of positive and good safety culture.

Eliminate the hazard– this can be done by not exposing yourself from the hazard.

Reduce: reduce the exposure to the hazard or changing the hazardous materials to a safer one that is use of water-based paint instead of enamel.

Isolate: de-energize the hazard or machinery by applying electrical or mechanical LOTO (lock out tag out) or putting barricade to separate the work from the public.

Control

Engineering control: putting additional equipment to minimize the hazard. It does not eliminate the hazard but rather isolate people from hazard, example having local exhaust ventilation.

Administrative control: putting processes or procedure to changes the way people work, employee training, signage and warning label,

Personal protective equipment– having gloves, helmet, mask, shoes, and so on.

Final take-always

- Be aware of the constantly changing work environment around you Identify ‘Line of Fire’ hazards in your risk assessment

- Eliminate the need to work in the line of fire where practicable

- Document and implement the controls of your risk assessment

- Monitor ‘Line of Fire’ hazards through adequate supervision.

THE BASIC PROCESS IS:

- STOP – Engage brain before you act

- LOOK – Identify any hazards

- ASSESS – What damage could those hazards causes

- MANAGE – Implement controls, tell others

- SAFELY – Complete the task

Remember, nothing that we do is so urgent that we cannot take time to do it safely. What you don’t know can hurt you and what you knew can help you.

Together, you and me and everyone of us let us be safety committed and honoring this commitment by working safely. Your safety is your responsibility…together we go home safely.

Remember if conditions change and the potential for a line-of-fire injury is identified we must use our Stop Work Authority immediately so that corrective action can be taken.

Your body is a moving object – keep it out of harms ways!

WE CAN WORK TOGETHER TOWARDS A MUCH CLEANER AND SAFER WAY!

If it is not safe… Don’t do it!

References

- Safety talk ideas

- P interest Safety Posters – Line of fire

- Online H&S Articles /Books / blogs. – From IOSH H&S Professional Members