Conveyor Belt Operation Safety

Volume 5, Issue 1, Jan – Mar 22

Conveyor Belt Operation Safety

Shahnawaz Rampuri

PhD (Scholar), Arunodya University – Arunachal Pradesh

Email id: shahnawazhs@yahoo.in

Abstract

In Industries, Several Method use to handling material from one location to other location in which one method is material handling through conveyor. Conveyor saves manpower, increase efficiency, save time and complete task safely. Conveyor has many positive benefits including few negative impacts whenever person come in contact with conveyor rotating parts during operation then this results accidents. In this Study, Potential Risk associated with conveyor has been identified & their control measure has been ensured. Few Incident data has been collected from heavy industries to know the actual condition of accident that occur during conveyor operation & recommendation has been made to prevent similar accident.

Keyword: Material Handling, Conveyor Operation, Conveyor belt Safety, Pull Cord Switch, Mechanical guard, Accident Prevention

1. Introduction:

In Industries, sequence of operation carries out to get desire product or services. To run sequence of operation different types of machinery, equipment and others items require. Material handling is a parts of sequence of operation in industries. Material Handling in industries manually or by mechanical means and conveyor is example of mechanical means to carry materials. Conveyor use in industries to carry material from one place or location to others. Conveyor is very helpful equipment or system that available in industries to save time and shift material in efficient and effective manner from one place to other. Conveyor has many advantages and similarly it has few disadvantages also. In other word, disadvantages may be known as negative impacts that arises due to poor method to use conveyor or not follow to safety rules during conveyor operation and this can results accident or other potential loss.

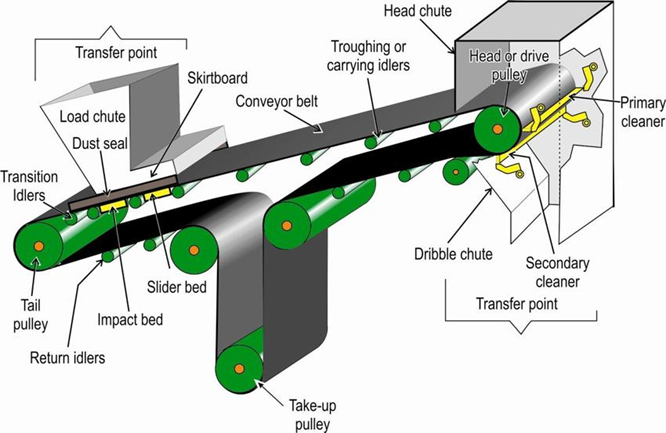

We cannot avoid to use of conveyor because this has been major equipments or system of industries that fully change materials handling procedure in efficient and effective manner. Conveyor may be different types and based of application this is to be used in industries. Spiral Chute Conveyors, Bucket Conveyors, Screw Conveyors, Power Driven Conveyors etc are few types of conveyor. Conveyor belt and their associated equipments use in industries as per job. Several sub-parts (components) use in conveyor system given in fig. 1.

Fig.1 Components of Conveyor Belt

2. Study based on Data Collected from Industries

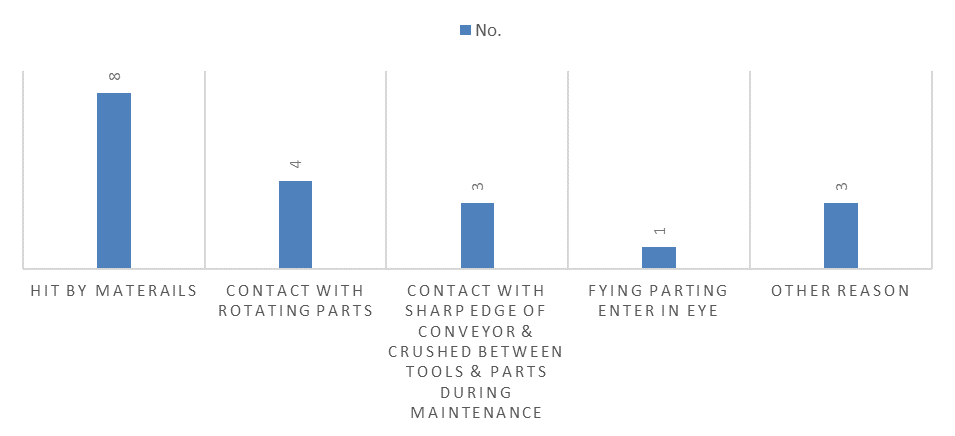

As per study, Conveyor related accident data has been collected from different sources from seven heavy including cement industries during year 2021, As per record available, Total accident occurred 19 No. In which 8 occur due to hit by material (Fall from Conveyor belt or Belt component failure and fall), 4 contact with rotating parts of conveyor, 3 Cut injury during conveyor maintenance job and crushed between tools & conveyor parts dung maintenance job, 1 flying particle enter in eye during inspection & 3 injuries was other reason such as person unbalance and Fall during maintenance and inspection. In Out of 19 Accident 3 accident was Lost Time injury and rest were minor (First Aid) injury.

Fig. 2, No. of Accident reason wise on based of Study

3. Hazard associated with Conveyor belt

Conveyor‐related hazards include inadequate or no guarded to gears, sprocket and chain drives, belts and pulleys, horizontal and vertical shafting, power transmission couplings & other rotating parts. Hazard means such sources that have potential to cause harm. Harm may be in the term of injury or fatality or damage to equipment whenever person expose from such sources or conveyor equipment fail.

Fig. 3, Conveyor System

3.1 Hazard associated with Conveyor Operation are:

Unguarded Rotating parts: Rotating parts of conveyor belt is potential sources of injury or harm if not guarded or inadequate guard provided. Nip point is main sources of potential injury of any personnel whenever come in its cpntact.

Failure of belt or associated parts: Failure of belt or associated components always results injury or other loss. Personnel can expose from such potential source.

Fall Hazard: Sometimes material fall from conveyor and this can hit to person and results injury. Similarly loose parts of conveyor also results injury due to fall.

Electrocution: Conveyor Belt generally operate through use of Power and Electricity is use to run motor like equipment and run to conveyor. Due to cable damage or current leakage in metal body parts of motor or other defects can result electrocution.

Apart from this, potential hazard associated with conveyor may be cut injury, entanglement, bruises or multiple injury. Fire Can also occur in few cases due to contact of hot material with belt. Basically, Conveyor belt use in industries are made of fire resistance materials, So less chance of fire with such belt but in case of fire huge losses occur if not control to fire immediate.

4. Safety Measure:

To operate conveyor Safely, Need to take adequate safety measure to prevent accident. Below are few safety measure

Pull Cord Switch: Ensure Pull cord switch with conveyor system. This will help to stopping conveyor in case of emergency. Emergency stop of conveyor will protect to personnel from major injury in case of accident occur. Pull cord switch install at the side of conveyor belt to stop conveyor instantly whenever accident happen or emergency occur.So always ensure suitable Pull cord switch with pull cord rope that should be in working condition.

Fig.4, Pull Cord Switch

Guard/Fenced to Conveyor: Adequate guard always ensures safety of personnel. Guard always keeps away to personnel or body parts of personnel from potential danger zone of conveyor. Nip point of conveyor is major sources of accident. Some time personnel body parts exposed between roller and conveyor and this results accident. So always ensure effective and suitable guard or fencing on rotating pars of conveyor.

Fig. 5, Fencing/Guard of Conveyor Parts

Deck plate/ To avoid Material handling: To avoid Falling of conveyor roller or any other parts of conveyor, need to provide Deck plate below conveyor belt on such location where are conveyor crossing to road.

Maintenance: Ensure effective maintenance to avoid failure of conveyor. Sudden Failure always results accident. Carry out inspection regular to identify any defect or potential sources of harm and take needful action accordingly.

Loose cloth or Jewelry: Avoid to wear Loose cloth or Jewelry during working near conveyor. Loose cloth or Jewelry of personnel can be entangled with rotating parts of conveyor and results of accident.

Display SOP & Signage: Display of Safe operating Procedure (SOP) & Signage will help to aware to people from potential risk and how to mitigate or control such risk

Training: Conveyor Safety related training must be deliver to employees including workmen. Awareness about conveyor safety will help to control conveyor operation related risk.

Supervision: Effective supervision always helps to eliminate unsafe practices. Supervision also helps to identify potential sources of harm that associate with conveyor.

Shut Down Procedure: Always ensure effective shut down system to carry out maintenance activity of conveyor. Lock out/ Tag out system must implement to conduct maintenance like activity of conveyor.

Apart from this use proper Personnel Protective equipments (PPE’s), always ensure proper power cable and connection with motor. Motor of conveyor should be protected from rain. Ensure body earthing of motor. Never clear Jam of roller during running condition, prepare safe operating procedure (SOP) and see their compliance. Avoid to carry welding or gas cutting like job near conveyor belt. Effective enforcement of Safety Management system will be always help to control risk related conveyor belt & their operation.

5. Conclusion:

Conveyor safety is very important in industries to control conveyor operation related accident. Inadequate safety measure during conveyor operation always results accident. In Conveyor several safety devices or factor require to prevent accident. Effective Safety measure helps to control personnel injury. Entanglement, Crushed, Cut, Bruises are few examples of Conveyor related accident. Nip Point is main sources of accident. All rotating parts of conveyor must be guarded, Pull Cord should be ensured with conveyor. Safe operating Procedure must be prepared. Maintenance should be carried out regularly. Training must be delivered for employees including workmen. Avoid to use lose clothes or chain near working conveyor. Adequate Safety measure will help to control conveyor related accident. Accident prevention through effective measure will be help to gain organization profitability, increase employee morale, increase reputation in market and success to business.